From textiles to paper!

10 July 2025

Transforming textile waste into paper products: A Quebec innovation at the forefront of the circular economy

By Éric Desnoes, researcher Innofibre

Every year, millions of tons of textile waste end up in landfills, despite their largely untapped cellulosic potential. In our latest study published in Cellulose, our team at Innofibre, in collaboration with several industrial partners, demonstrates that it is possible to transform textile residues into functional papermaking pulps—paving the way for new molded products.

From clothing to molded pulp

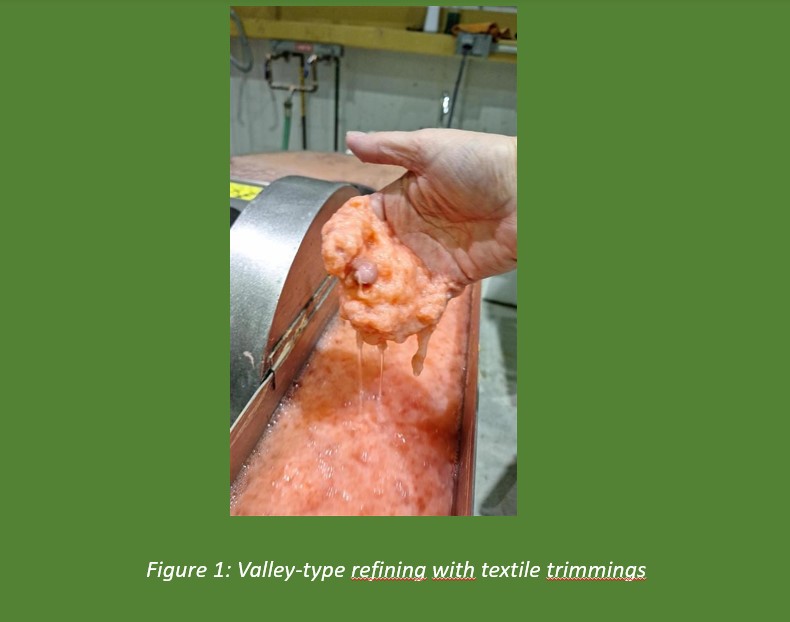

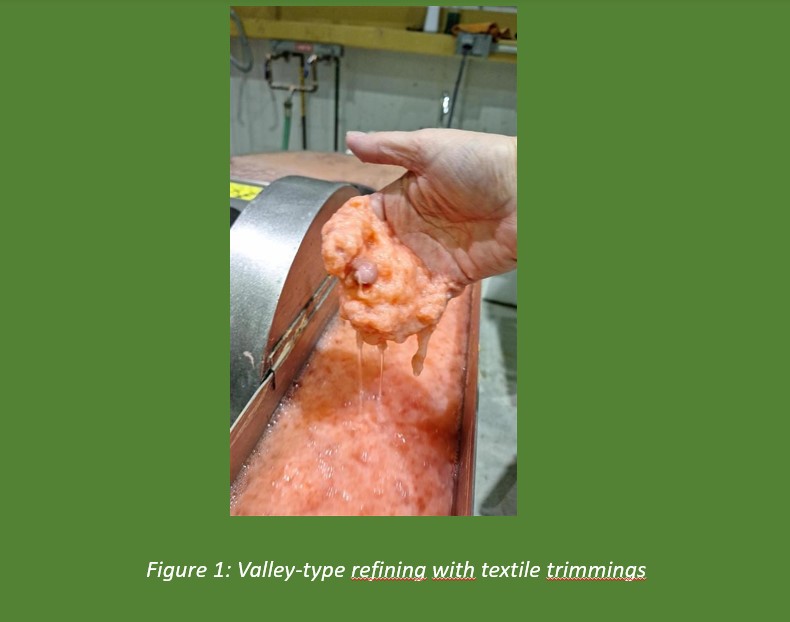

Our research focused on recycling cotton offcuts supplied by the Montreal-based company Atelier b. Using a Valley-type refiner, we successfully produced a fibrous pulp from these textiles. By adjusting the refining time, we studied its impact on the mechanical and physical properties of the resulting paper.

An optimal refining time allowed us to achieve a balance between elongation, burst strength, and tear resistance, while ensuring density and air permeability consistent with industry standards. However, excessive refining led to fiber shortening and excessive fines production, which negatively impacted material performance.

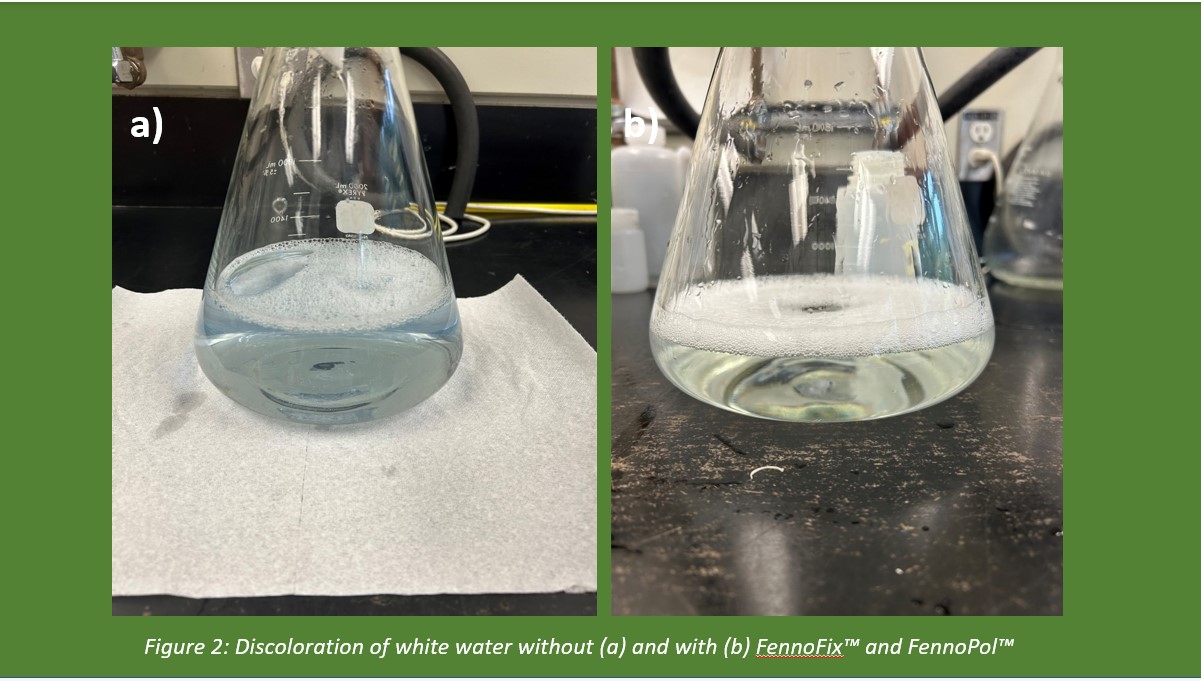

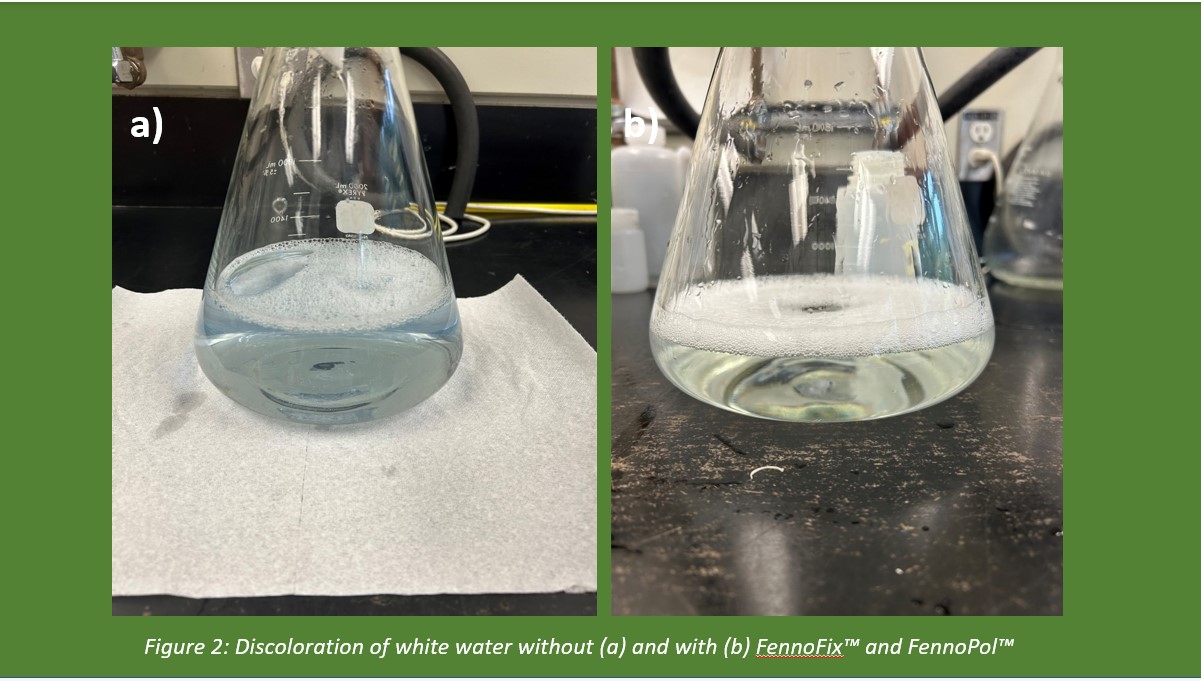

An unexpected challenge: pigments

One significant issue encountered was the leaching of textile dyes during the refining process. These pigments, released into the process water, present an environmental challenge. We tested papermaking retention and fixative additives (FennoFix™ and FennoPol™), which significantly reduced dye concentration in the white water a promising step toward a more environmentally friendly treatment process.

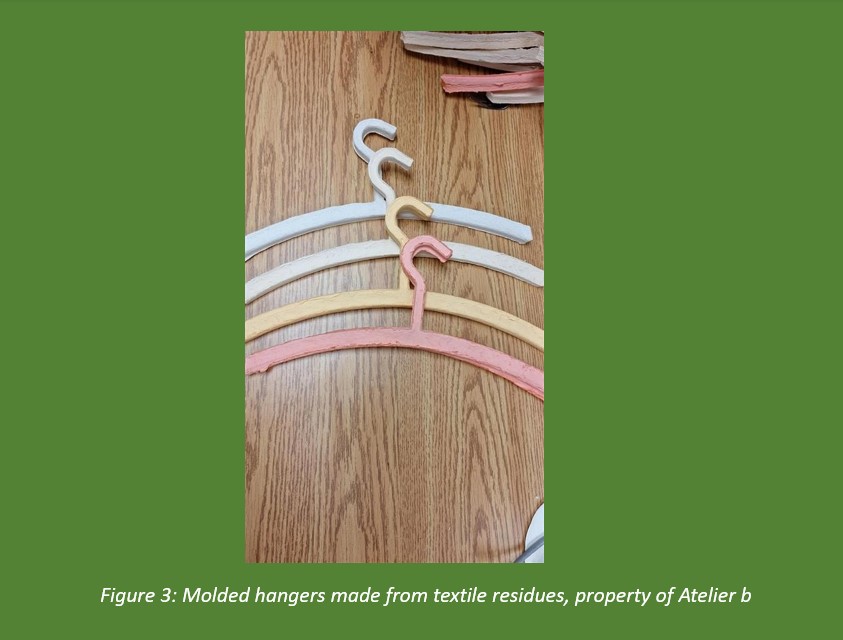

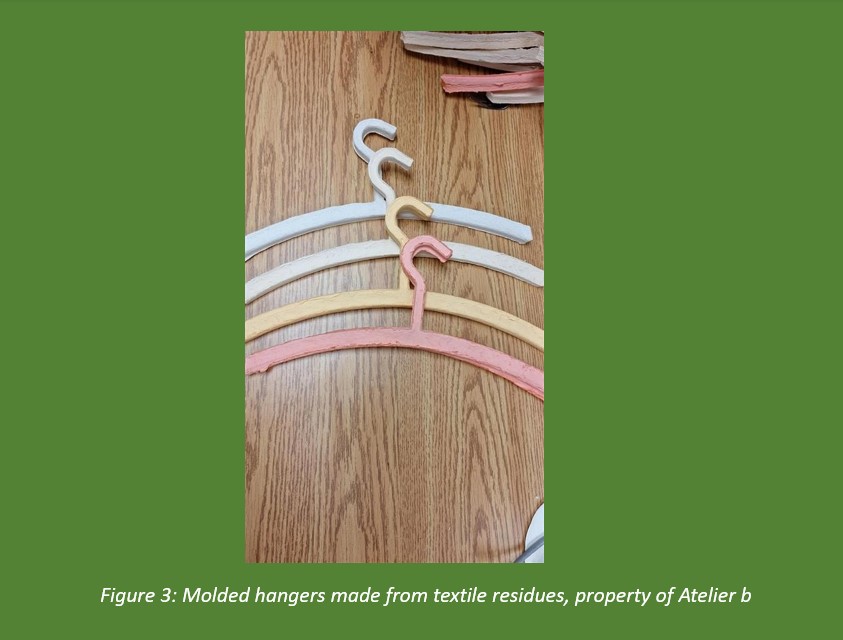

A concrete application: the molded hanger

To demonstrate industrial feasibility, we designed a 3D mold to produce molded hangers from our refined textile pulp. The result? A rigid, lightweight product entirely made entirely from recycled textiles ready to replace plastic hangers in commercial settings.

Toward circular papermaking

This study opens new avenues for Quebec’s pulp and paper industry. By integrating textile residues an abundant and underused resource into pulp manufacturing processes, we address both the shortage of forest-based raw materials and the growing demand for sustainable practices. This approach aligns fully with circular economy principles and the valorization of local waste streams.

Acknowledgments

This research was made possible thanks to support from NSERC (CARD2-566875 grant), Atelier b for the textile offcuts and hanger development, and Kemira for the chemical additives.