A tornado struck Innofibre. Did you know that?

7 August 2025

A tornado struck Innofibre. Did you know that?

By Gaston Michaud, Research Engineer, Innofibre

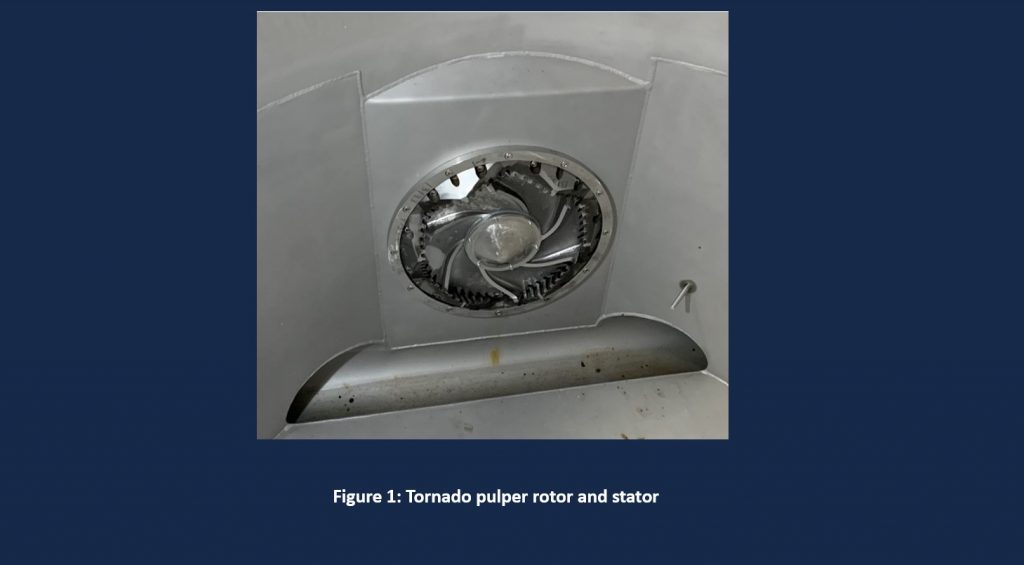

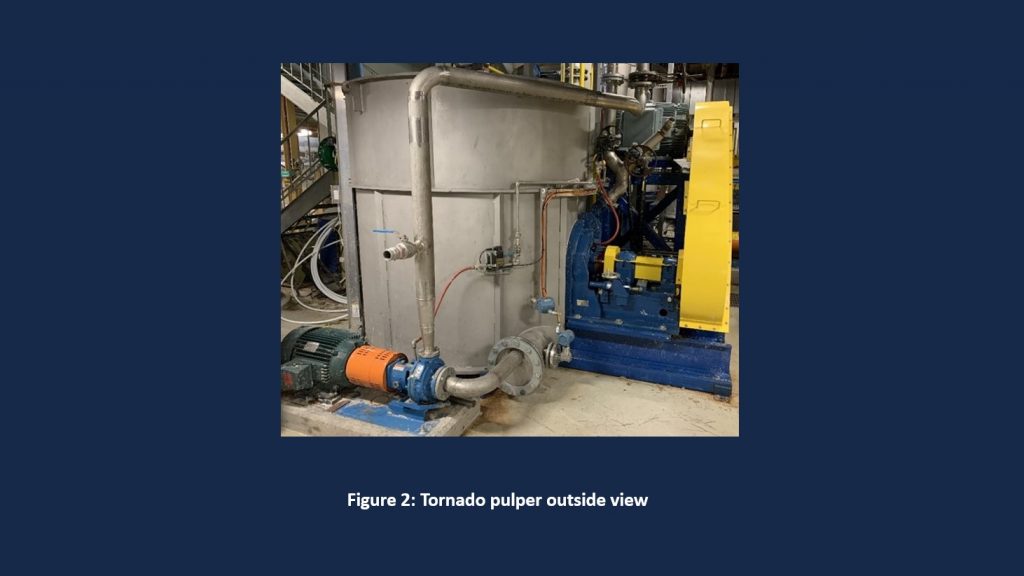

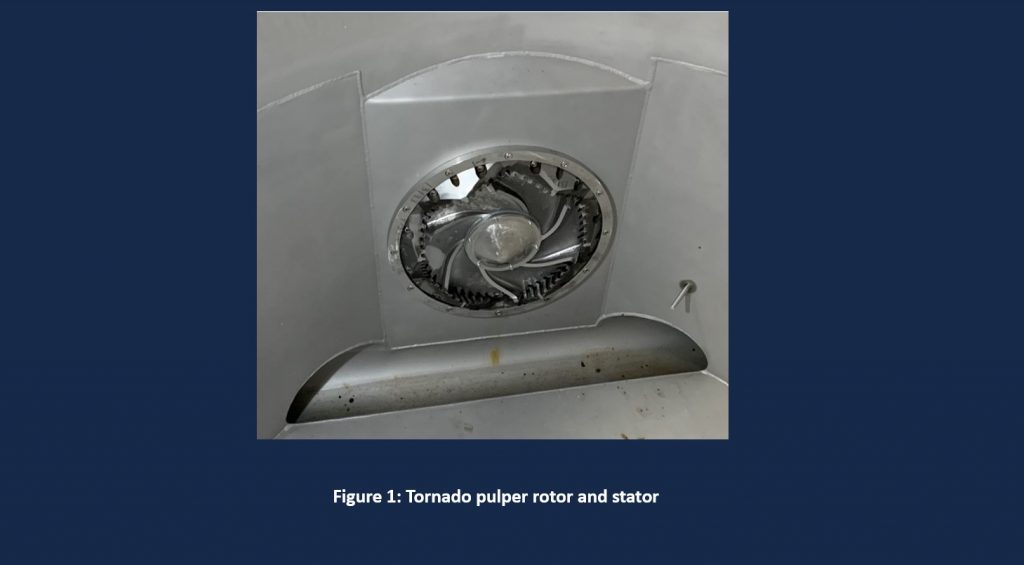

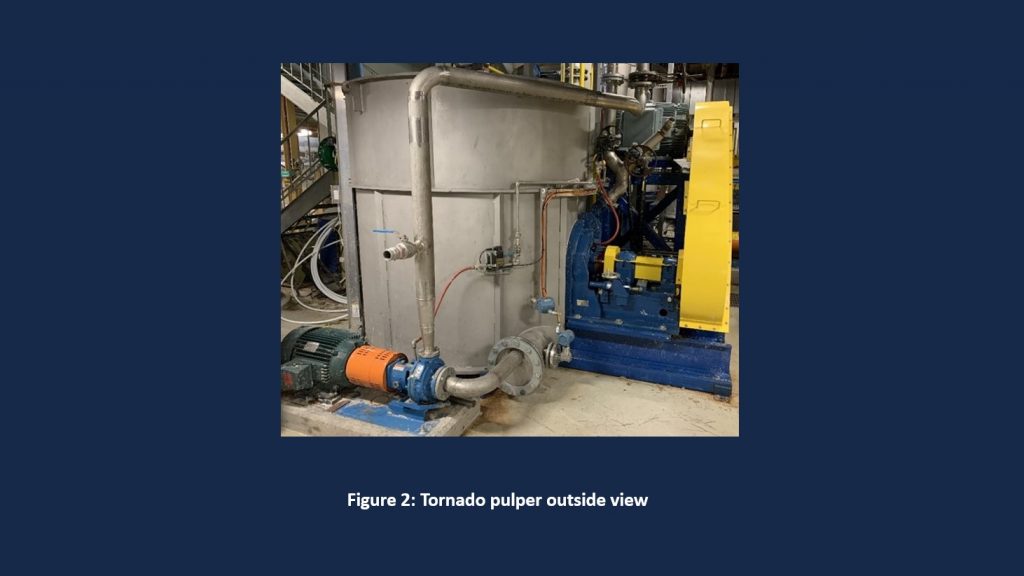

In early 2020, Innofibre installed a new pulper in its pilot plant. The pulper, manufactured by Bolton-Emerson, is called Tornado. In 2024, Kadant acquired this technology. The pulper is installed sideways on a tank. It is unique in that it has a rotor surrounded by a stator. The gap between the rotor and the stator can be adjusted by moving the rotor along its axis.

The Tornado pulper was designed to pulp materials that are known to be difficult, if not impossible, to pulp using conventional pulpers. It is particularly effective for heavily sized paper/paperboard, shoeboard, and floor covering paperboard that is impregnated with latex.

It can also be used to pulp long natural fibers such as cotton, hemp, and flax. Generally, a refiner is used with the Tornado pulper to achieve this.

The Tornado pulper is designed to achieve a high shear rate during operation. The rotor is equipped with vanes, at the ends of which there is a set of bars and grooves. On the periphery of the rotor, the stator is also equipped with bars and grooves. During rotation, the rotor bars and stator bars interact like scissors on the material to be pulped, resulting in the intense shearing action produced by this machine.

The Tornado pulper also acts as a pump thanks to the rotor vanes. The material that passes between the rotor and the stator is expelled into a chamber located at the rear of the pulper. This chamber has a tangential outlet from which the material can be returned entirely or partially to the pulper tank.

This pulper can be operated in batch or continuous mode. In batch mode, a quantity of material is pulped and recirculated for a predetermined time, then the resulting pulp is pumped into a discharge tank. In continuous mode, part of the pulp is recirculated and the other part is sent to the next process stage. The proportions can be adjusted as needed. To maintain the level, material and water are continuously added to the pulper tank.

The Innofibre Tornado pulper has a diameter of 610 mm (24 in.). It is equipped with a 150 kW variable speed motor. The rotor is driven by a set of pulleys and belts. The maximum rotation speed of the rotor is 650 rpm. It is equipped with an 8,000 L tank with a working volume of 4,000 L. It generally operates at a consistency of between 3% and 6%, depending on the material being pulped.

The Tornado pulper is an important piece of equipment to explore for improving existing processes or developing new products. To learn more about the Tornado pulper, please contact the manufacturer. To test this equipment with your own raw materials, please contact Innofibre.