Thermochemical conversion of biomass: ashes have so much to say.

By Maude Tessier-Parenteau, Research, Innofibre

Thermochemical conversion of biomass is a key research focus at Innofibre. The center operates several equipment for combustion, pyrolysis, and soon, gasification projects. Aiming to decarbonize various industrial sectors, the Innofibre team is conducting several projects evaluating the potential of substituting fossil coal with renewable biomass in multiple applications.

With any biomass thermochemical conversion comes ash!

Essentially, ashes are the non-combustible mineral part of a substance. The chemical composition and ash content of a biofuel vary significantly depending on the type of biomass. For instance, bark-free wood typically contains less than 1% ash, whereas bark can contain up to three times more. Agricultural residues can have ash content exceeding 5%. The presence of heavy metals, chlorine, nitrogen, and sulfur in ashes is crucial data as it significantly impacts the final application. Some components increase fouling of thermochemical conversion equipment. For example, certain ashes tend to melt at lower temperatures then upon cooling, form clinker or slag. This hard solid residue coats the heat exchange equipment surfaces, and drastically reduces performance.

Innofibre has acquired an Ash Fusion Determinator for biomass.

Apart from analyzing the chemical composition of ashes, this device helps understanding the physical behavior of ashes found in different sections of a biomass boiler circuit, in pyrolysis or gasification equipment. This analyzer allows comparison of the tendency of ashes from various types and qualities of solid biofuels to produce molten deposits or cause sticky residues that lead to harmful agglomeration affecting the proper operation of thermochemical conversion equipment.

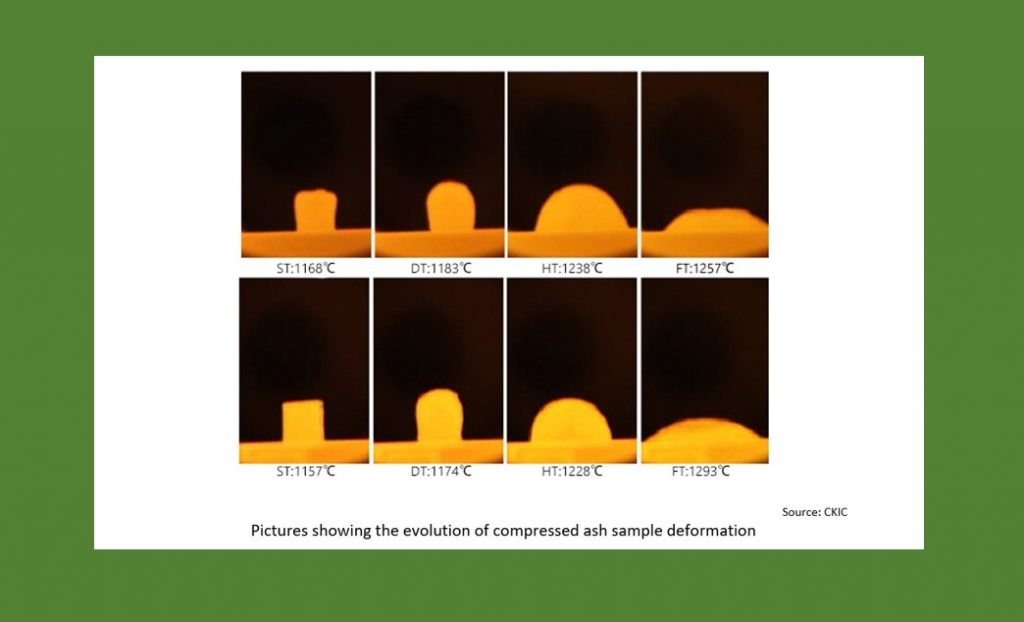

Ashes are composed of a mix of several minerals and don’t have a fixed melting point but rather a range of fusion temperatures. The ash fusion analyzer determines characteristic temperatures during the fusion of ashes produced from biomass or other solid fuels according to standards such as ISO 21404:2020 (solid biofuels), CEN 15404 (solid recovered fuels), ASTM D1857 (coal and coke), and similar norms.

The analyzer observes the behavior of ash samples, previously compressed into a cylinder or cone shape, subjected to a constant temperature rise rate up to 1,500 °C in a controlled atmosphere (air, nitrogen, carbon dioxide, carbon monoxide, or hydrogen). A multispectral camera diffuses and records real-time data for up to 10 samples analyzed simultaneously on a rotating carousel. Measurements of sample deformation throughout the analysis determine hemispherical fusion and fluidity temperatures.