Our equipment

Thermoformed pulp

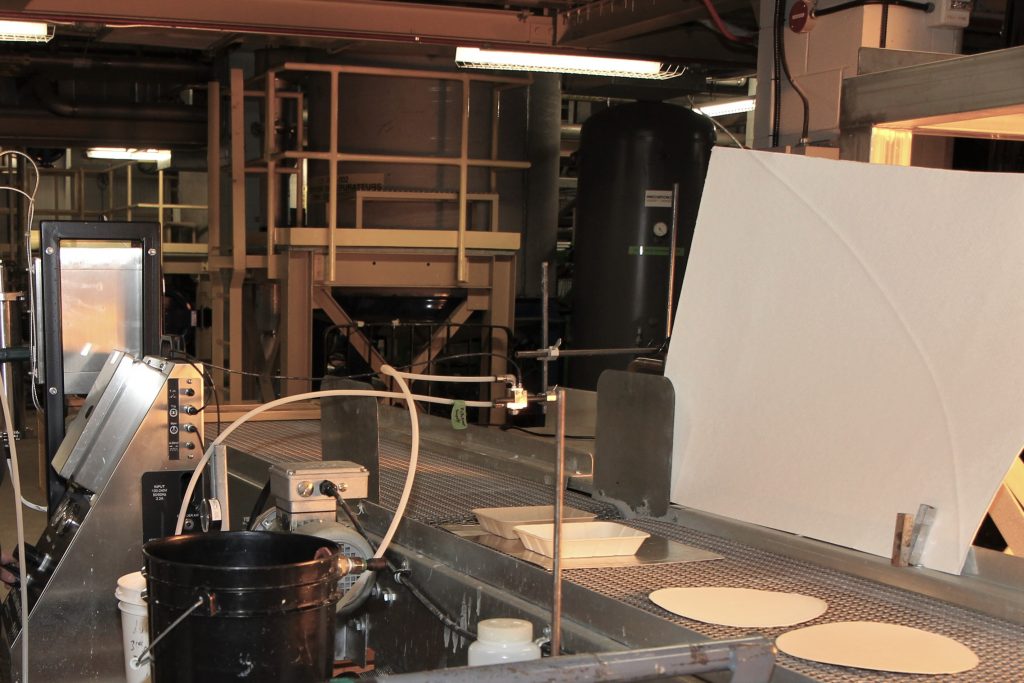

Thermoforming system

Characteristics

- MSI PME, MecSmart

- Model: TF-45

Particularities

- System consisting of a forming mould, a transfer mould and two drying press moulds.

- Adjustment of the thickness of the parts by distance control.

- System for heating the pulp.

- Easily interchangeable aluminum mould to adapt to new pieces.

- Possibility to integrate the resin mould technology.

- Possibility of adding additives to the pulp by means of a dosage system

Uses

Production of Type 2 cellulosic thermoformed parts (without pressing) or Type 3 (with pressing).

Technical specs

| Max Product Size L x W x H | 1524 mm x 533 mm x 76.2 mm (60 inch x 21 inch x 3 inch) |

| Platen configuration | 5 individual platens to manufacture up to 5 different products of 304 mm x 533 mm |

| Max Capacity | 45 kg per hour dry weight |

| Min pulp quantity | 4 kg dry weight |

| Drops per minutes | 2 pending product thickness and geometry |

| Moulding Tank Capacity | 330 L – Max Capacity of 756 L |

| Vacuum System | 685 mmHg adjustable |

| Moulding System | Servo driven rotary head, vacuum system |

| Blow off System | 6.9 barg and 2.8-4.2 m3/min adjustable |

| Transfer System | Servo driven y-axis and z-axis programmable, vacuum system, blow off system |

| Heating System | Multi-zoned and adjustable, upper and lower platens heating, upper and lower tools heating |

| Thermoforming System | Servo driven vertical z-axis multi positions, heating system, vacuum system, blow off system |

| Additive System | 4 reservoirs with individual pumps (3 low dose materials and 1 for colour) |

| Die Wash System | Tooling Die Wash System at low and high pressure (33 barg) |

| Stacking and Unloading System | Integrated Stacking System and Transfer Conveyor to the operator for packing |

3D Printer

Characteristics

- Manufacturer: Stratasys

- Model: Fortus 450 MC

Particularities

Several types of resin: (ABS-M30, ASA, PC, FDM nylon12, Ultem 1010, Ultem 9085).

Uses

- Production of moulds for the cellulosic moulding process

Technical specs

| Size of parts | 16”x14”x16” |

| Layer thickness |

|

Spraying System

Characteristics

- Manufacturer: Spraying System

- Model: 1550+ autojet modular spray system

Particularities

- Spraying controller

- Double diaphragm pneumatic pump

- Air input regulator and filter

- Liquid pressure regulator, manometer, and output filter

- Recirculation and bypass gate valves

- Pulsajet nozzles

- HD15 heating system

Uses

Surface spray coating

Technical specs

| Nozzle opening | 5 to 100% |

| Fixed conveyor-mounted system (15–60 ft/min) | |