Our equipment

- No categories

Pilot equipment

Hammer Mill (Mix Mill type)

Characteristics

• Hammer milling system

• Multiple grinding screen sizes available

Particularities

• 6″ discharge hopper with aspiration system

• Sets of screens with various diameters

• Unit mounted on a mobile platform

Uses

Suitable for forest and urban biomass residues

Technical specs

Manufacturer : Law-Marot-Milpro (LMM)

Model : Milpro Promega 1000

Rotation speed : Drum rotation speed of 1800 RPM

Grinding Configuration : 15 swinging hammers

Available screens :

| Metric units | Imperial units |

| mm | in |

| 19 | 3/4 |

| 15 | 5/8 |

| 9 | 3/8 |

| 6 | 1/4 |

| 4,5 | 3/16 |

| 3 | 1/8 |

Hammermil

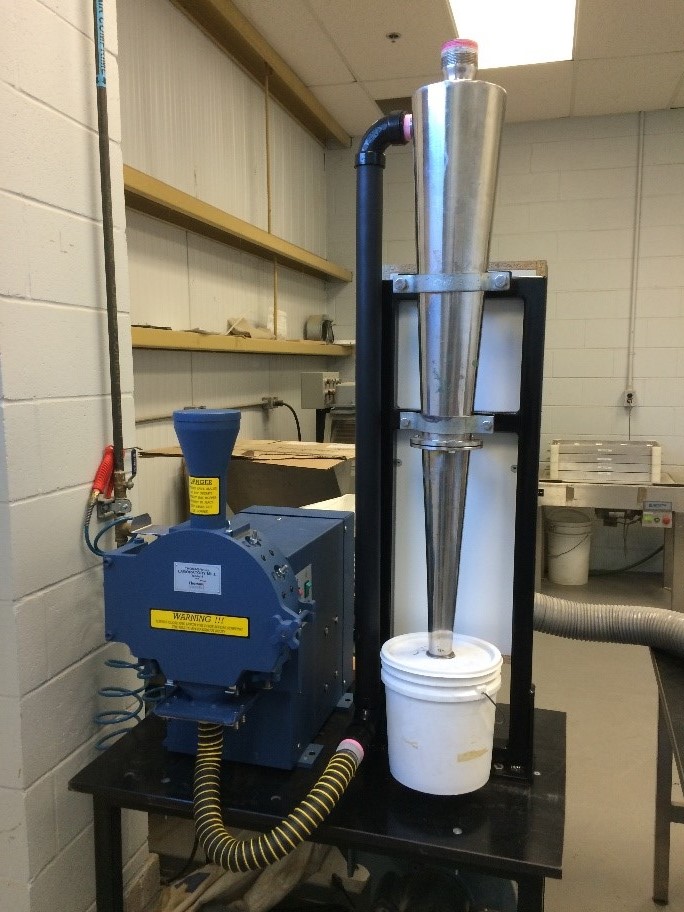

Characteristics

- Milling and attrition of forest, residual or inorganic fillers according to different sieving grids

Particularities

- Hammer grinding at 3,600 RPM

- Sieving screens from 20 mm to 2 mm

- 55 HP motor and integrated cyclone

Uses

- The Hammermill type hammer mill allows the fractionation of different bio-based or inorganic materials in order to obtain a more uniform particle size at the end of the process. The fan and cyclone separates fines and dust to collect the right material at the bottom of the cyclone.

Technical specs

- Manufacturier : Radviliskis

- Type: Hammer Mill 55

- Engine: 55 HP

- Diameter of the sieves: 72 cm

- Throughput: ±500 kg/hour (depending on the material

Rodrigue Hammer Mill

Characteristics

- Fractionation of forest, residual or inorganic fillers according to different sieving grids

- Hammer mills

- Various grinding screen sizes

Particularities

- Hammer grinding at 1,800 RPM

- Sieving grids from 20 mm to 6 mm

- 125 HP motor and integrated cyclone

- 13,000 cfm centrifugal fan at the discharge

- Choice of cutting geometry (knife vs. hammer)

- Unit mounted on a mobile platform

Uses

- The Rodrigue hammer mill makes it possible to split different bio-based or inorganic materials in order to obtain a more uniform particle size at the end of the process. The fan and cyclone separates fines and dust to collect the right material at the bottom of the cyclone.

- Suitable for forest and urban biomass residues

Technical specs

- Manufacturer: Rodrique-Métal

- Type: Hammer Mill LV 410 -30

- Engine: 125 HP

- Diameter of the sieves: 75 cm

- Throughput: ± 1 ton/hour (depending on the material)

- Rotational speed: Drum rotation speed of 1,800 RPM

- Fragmentation configuration: 30 pivoting hammers/knives

Weima Pusher Slow Mill

Characteristics

- Material Splitting According to Different Sieving Grids

Particularities

- Slow grinding at approx. 100 RPM

- Sieving grids from 20 mm to 6 mm

- 10 HP motor and integrated pusher

Uses

- The slow mill is useful for splitting different bio-based or inorganic materials to achieve a more uniform particle size at the end of the process. The pusher avoids bridging the material to ensure constant flow rates of around 300 kg/hour.

Technical specs

- Manufacturier : Weima

- Type: Pusher Slow Crusher WL6S 30

- Engine: 10 HP

- Sieve diameter:Available grids: 19 mm; 6 mm

![]()

Crusher – crumbler

Characteristics

- Attrition of particles into homogeneous fines

Particularities

- 2 independent entrances with different teeth (straight and angular)

- Precise adjustment of the tooth rollers

- Attrition from coarse to ultra fine (± 1000 um)

Uses

- Attrition de granules en particules fines sans générer de poussière importante

- Réduction des grains en farine

Technical specs

- Manufacturier : Millpro

- Type: Low Dust Crumble

- Engine: 11 HP

- Flow rate: ± 100 kg/hour

Trommel-type rotary screener

Characteristics

- Three-section, variable-angle screening and separation unit

Particularities

- 3 Programmable heating elements

- Temperature control up to 1000 °C

- Gas capture and analysis capability

Uses

- Separation of heterogeneous materials through three separate screens continuously. The material is transported by a feed auger to the sieving surface where a high-speed rotor forces the particles of the desired particle size through three grids.

Technical specs

- Manufacturier :LMM

- Type: TR60 lump breaker

- Throughput: ± 100 kg (depending on grain size)

- Sieve diameter: 46 cm

Horizontal Tube Pyrolysis Furnace

Characteristics

- Heating unit with oxygen control

Particularities

- 3 Programmable heating elements

- Temperature control up to 1000 °C

- Gas capture and analysis capability

Uses

- The pyrolysis furnace can heat all carbon-based materials (wood, plastics) in the absence of oxygen in order to thermally decompose the material and improve certain properties

Technical specs

- Manufacturier : Lindberg blue

- Type: Horizontal Tube Furnace

- Temperature: adjustable between 25 – 1000°C

- Length:132 cm

- Width: 56 cm

- Height: 66 cm

- Steel tube: 180 cm x 10 cm diameter

![]()

Belt dryer

Characteristics

- Natural Gas Belt Dryer

Particularities

- Two drying compartments with variable temperature up to 150 °C

Uses

- The biomass dryer is used with any type of biomass that requires thermal conditioning

Technical specs

- Manufacturier : Airex industries

- Type: Belt dryer

- Speed: Speed adjustable between 0.1 to 1.75 RPM

- Specifications: Two Maxon Ovenpack 425 fireheads with a capacity of 2.5 MMBTU natural gas

- Temperature: Adjustable temperature range between 55°C and 150°C

- Power Fan: 15000 CFM

- Exhaust fan: 6500 CFM

- Throughput: 1 Ton per hour to dry an input with 35% to 10% moisture content

Extrusion unit

Characteristics

- Extrusion unit for biochar and biomass mixtures

Particularities

- Single screw extruder with possibilities of biomass mixes

- Options for different output dies and various bulk densities

- Variable rotational speed from 0 to 50 rpm

- Feeding into the extruder in continuous mode

Uses

- Production of block shapes biochar or densified biomasses

Technical specs

- Maximum outlet diameter of 4 inches

- Quantity of inputs to be densified by extrusion up to 300 kg/hr

Cutting mill

Characteristics

- Cutting mill

Particularities

- Rotor made of tungsten carbide

- Variable speed : 100 to 3000 rpm

- Sample size: 5 liters maximum

- Interchangeable bottom sieves (1 mm, 2 mm, 8 mm)

Uses

Cutting mill is suitable for the grinding of soft, medium-hard, tough, elastic, fibrous, and heterogeneous mixes of products.

Technical specs

| Manufacturer | Retsch |

| Model | SM 300 |

| Motor | 3 kW |

| Sieve sizes | 1, 2 or 8 mm |

Rotary kiln system for pyrolysis and activation

Particularities

3 separate heating zones operating at up to 1000 oC

Flowrate of inert gases and oxidant from 0 to 30 ml/minute

Rotating speed from 0 to 20 rpm

Quantity of input to be pyrolysed or activated up to 10 kg per cycle

Uses

Production of activated carbon

Thermoconversion of biosourced materials by pyrolysis

Technical specs

Volume of the high thermal resistance rotating cylinder of 130 L

Diameter of the rotating cylinder of 32 cm and a length of 160 cm

Briquetting presses

Characteristics

Industrial briquetting presses

Particularities

- Robust model suitable for several types of biomass

- System including a large hopper allowing a large load of material

Uses

The briquetting system is designed to produce energy logs or to densify biomasses to optimize their transport.

Technical specs

| Manufacturer | Weima |

| Model | TH 814 |

| Production rate | 180 kg/h |

| Briquette diameter | 80 mm |

| Brick length | Variable from 50 to 80 mm |

| Engine power | 11 kW |

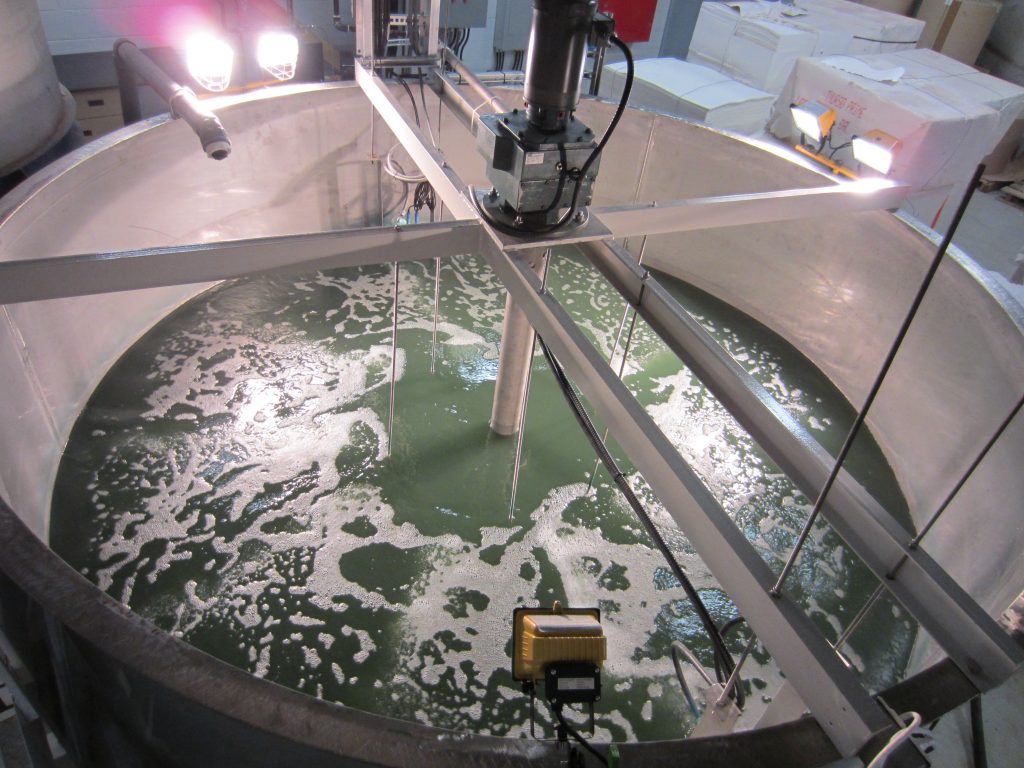

Algafuel TM – Pilot Tank

Characteristics

- Deep circular tank

- Designed for growing in mixotrophic mode

- Cultivation in phototrophic mode also possible

Particularities

- Mechanical stirring system with rotor and moto-reduction

- Aeration / CO2 injection system with tubular diffusers

- Temperature control system

- pH/ORP/temperature probes

- Data acquisition and transfer console

Uses

Production of algal biomass on a pilot scale for the validation of applications

Technical specs

| Manufacturer | Algalab |

| Model | Algafuel 3300 |

| Diameter | 3.3 m |

| Height | 1.5 m |

| Volume | 10m3 |

Sequoia boiler with emission sampling platform

Characteristics

- Manual biomass feeding and ash removal

- Flue gas sampling platform

Particularities

- Different types of heating unit are available: water plate, dragons…

- System for recording operating conditions

Uses

Study and evaluation of the combustion of different types of residual biomass

Technical specs

| Manufacturer | Séquoia Industrie |

| Model: | GE 60 SP Standard |

| Cooling liquid | Water (830L) |

| Combustion blower | 2 (primary and secondary) |

| Pressure | Atmospheric |

| Capacity | 750 000 Btu |

Pyrolyser

Characteristics

- Cyclonic bed reactor

Particularities

- Direct heating of the biomass

- Once the pilot unit is preheated, the process produces its own energy.

- The pyrolysis gases are recycled and burned in the combustion chamber.

- System for recording operating conditions

Uses

- Production of biochar in various grades

Technical specs

| Manufacturer | Airex Energie |

| Model | Carbon FX |

| Capacity | 125 kg/h |

| Maximum operating temperature | 480°C |

Harvesting system for microalgae cultivated in pilot tank

Characteristics

- System with a sedimentation tank for biomass pre-concentration and a circular vibrating separator for the separation of solids and liquids

Particularities

- 1 m³ settling tank feeding the circular vibrating separator by gravity

- The circular vibrating separator is a sieving device that vibrates around its center of gravity.

- The use of flocculants may be necessary depending on the strain harvested

Uses

Harvesting of the algal biomass cultivated in the pilot basin.

Technical specs

| Manufacturer | Sweco |

| Model | Vibro-Energy Separator |

| Sieve | 400 meshes per inch Thread diameter 25 µm Pores 37 µm |

| Harvesting capacity | Between 500L and 1 000L/h |

Carbonization system

Characteristics

- Carbonization system made up of four retort furnaces

Particularities

- Each retort can be controlled separately

- Indirect biomass heating

- One the pilot unit has been preheated, the process generates its own energy

- Pyrolysis gases are recycled and burned in the post-combustion chamber

Uses

Production of biochar in various grades

Technical specs

| Technology | Retort furnace |

| Combustion chamber | 1 combustion chamber:

|

| Furnaces and tanks | 4 cylindrical furnaces :

|

| Capacity per tank |

|

Granulating machine

Characteristics

- Industrial granulating machine

Particularities

- Wide choice of granulation dies (diameter, compaction ratio)

- Possibility of injecting binder material at a controlled flow rate and pressure

- Complete assembly including hammermill, cooling column and bagging silo

- Complete stainless-steel kit for food production

Uses

The granulation system is designed to produce energy pellets, animal feed and biofertilizers.

Technical specs

| Manufacturer | Radviliskis machine factory |

| Model | OGM-1.5A |

| Technology | Spinning ring |

| Production pace | Variable from 800 kg/h to 1500 kg/h |

| Granulation die | Several available compression ratios and granulation diameters |

Hot Press

Characteristics

- Hydraulic heating press custom made by Ovotech

Particularities

- Adjustment of time, temperature and pressing height

- Thermocouple sensors to control pressing temperature

- Possibility to heat the two trays at different temperatures

- Adjustable closing and degassing times

Uses

The hydraulic press is used in the development of agglomerates based on biomass residues.

Technical specs

| Manufacturer | Dominion Hydraulic Press / Ovotech |

| Pressure | 110 tonnes |

| Preform size | 500 x 500 mm |

| Temperature | Variable, up to 235 ˚C |

Pressurized reactors

Characteristics

- 740L reactors with horizontal agitation

Particularities

- Heating by steam injection

Uses

- Pretreatment

- Reactive fractionation

- Extraction

Technical specs

| Manufacturer | Valmet |

| Volume | 0.74 m3 |

| Heating mode | Direct steam injection |

| Maximum pressure | 800 kPag |

| Maximum temperature | 175°C |

| Consistency | 15-40% |

| Motor | 3.7 kW |

| Agitator speed | 4 rpm |

Pressurized reactors 250L

Characteristics

- Manufacturer: Solinox

- Model: 250L

Particularities

- Pressurized reactor for biomass processing

- Explosion-proof reactor class 1 division 2 for use with flammable products

Uses

- Biomass pretreatment

- Reaction on biomass

Technical specs

| Volume | 250 |

| Max temperature | 175 °C |

| Max pressure | 2500 kPa |

| Heating type | Steam |

| Cooling | Water |

| Electrical classification | Class 1 division 2 |

Gas sampling system

Characteristics

- EPA-compliant sampling system

Particularities

- Isokinetic sampling for particles, metals, and semi-volatile organic compounds

- Sampling of SO2, NOx and formaldehyde

Uses

- Sampling of air emissions from stationary sources

Technical specs

| Manufacturer | APEX INSTRUMENTS |

| Model | SK-M5DP, SK-606 et CK-7A9 |

| Equipment and accessories | Sampling console, external pump, 2 heated boxes, 2 3-foot probes, liner kits and glass and stainless-steel nozzle |

Adhesive blender

Characteristics

- Vaporization of PF/ UF/ pMDI/ Tannins, etc. binding material, at a viscosity of up to 1000 Cp

Particularities

- Adjustable spraying pressure

- Variable angle rotative blades

- Mounted on a skid

Uses

The adhesive blender is used to create matrix/reinforcement formulations for use in hot pressing and pellet production.

Technical specs

| Manufacturer | IMAL |

| Model | LGB-300 |

| Capacity | 300 dm3 |

| Motor | 1.1 kW |

| number of nozzles | 4 |

Atmospheric reactor

Characteristics

- 150L reactor with agitation

Particularities

- Indirect steam heating

Uses

- Pretreatment

- Reactive fractionation

- Extraction

Technical specs

| Manufacturer | Lee |

| Volume | 0.15 m3 |

| Heating mode | Indirect steam |

| Enveloppe calorifugée | 178°C à 860 kPag |

| Consistency | 15-40% |

| Motor | 0.75 kW |

| Agitator speed | 38-190 rpm |

Twin-screw extruder

Characteristics

- Manufacturer: Entek

- Model: E-max 27 mm

Particularities

- Extruder specially designed for the thermo-chemical treatment of biomass and fiber / plastic composites

Uses

- Extrusion of fibre/plastique composites

- Biomass pretreatment

- Reaction on biomass

Technical specs

| Screw—diameter | 27 mm |

| Screw—length | 1296 mm |

| Length/diameter ratio | 48 |

| Maximum temperature | 246 °C |

| Motor | 30 kW |

| Solid feeder | 1 |

| Liquid feeders | 2 |

Slow Mill

Characteristics

- Mechanical prefractionation of biomass

Particularities

- Tolerance to foreign bodies and the presence of minerals

- Mounted on a mobile platform

Uses

Slow milling is used to standardize the size of the residues in order to optimize their separation, drying and processing.

Technical specs

| Manufacturer | Weima |

| Model | WLK-4 |

| Number / Type of hammers | 14 / concave hammers |

| Rotation speed | 100 rpm |

| Available grates | 12 mm, 30 mm, 60 mm |

Hammer Mill

Characteristics

- Hammer mill

- Different sizes of milling grates

Particularities

- 13,000 cfm centrifugal fan at the outlet

- Choice of cutting geometry (knife vs. hammer)

- Unit installed on a skid

Uses

Adapted to forest and urban biomass residues

Technical specs

| Manufacturer | Rodrigue-Métal |

| Model | LV 410-30 |

| Rotation speed | Drum rotation speed of 1800 RPM |

| Fractionation configuration | 30 hammers / swivel knives |

| Output | Grinding output of 12 TMV/hour |

Vibrating sifter

Characteristics

- Configuration with 2 screening decks (16’ x 4’) and 3 output particle size gauges

Particularities

- Several choices of screens (perforated fabric, woven screen, or Flex-Mat)

- S, T or D mesh design

- Mobile structure on caterpillar treads

Uses

- Ideal for high-precision sifting

- Suitable for multi-material flows composed of wood, plastics, minerals, and others

Technical specs

| Manufacturer | KPI-JCI |

| Model | FT5162i |

| Configuration | 2 screening decks (16’ x 4’)

3 grain sizes at the output |

| Screens | Choice of mesh design (D, T, S) |

| Minimum grain size | Anti-clogging screening from ¼“ |

Optical sorter

Characteristics

- High-power, high-resolution binary and ternary separation

Particularities

- Near infrared (NIR) and colour (VIS) sensors

-

Possible detection of ferrous and non-ferrous metals by controlled induction (IND)

- High power and high-resolution separation (HP/ HR)

- Possibility of ternary sorting

- Mounted on a skid

- In October 2024, Innofibre acquired a new electronic and software platform, FLOW & CNS+ (Central Nervous System), which includes the latest algorithms and technological advancements. The new platform offers a wide wavelength range, the addition of the “Profile Detection” module, the “Top Speed” option, and the integration of the “Vision” color detector. These features will significantly enhance optical sorting operations (detection of black compounds and modification of air jet flows during the process).

Uses

Versatile equipment adapted to municipal, industrial, commercial and construction residues.

Technical specs

| Manufacturer | Pellenc ST |

| Model | Mistral + DVI 1600 mm |

| Spectrum | Visible (VIS) and near-infrared (NIR) spectrum |

| Output | Hourly separation rate of up to 15 TMV/hour |

| Minimum detection dimension | ½“ |

Densimetric separation

Characteristics

- Air-knife separation with adjustable power

Particularities

- Separation curtain adjustable in both axes (x-y)

- Adjustable air-knife power

- Mounted on a skid

Uses

- The equipment can be used to separate materials according to their specific weight.

- Ideal for the pre-treatment of biomass and municipal residues

Technical specs

| Manufacturer | Groupe Mayrand |

| Model | 1600 mm |

| Speed | Acceleration conveyor with variable speed |

| Curtain | Separation curtain position adjustable in both axes |

Pressurized reactors (100ml)

Characteristics

- Manufacturer Parr

- Model : 100 mL

Particularities

High pressure and high temperature reactor

Uses

- Hydrothermal biomass liquefaction

- High temperature and high-pressure reaction

Technical specs

| Volume | 100 mL |

| Max temperature | 500 °C |

| Max pressure | 5000 PSI |

| Heating type | Electric heating mantle |

| Cooling | Open air |

| Agitator | Propeller or turbine |

Pulveriser Thomas Wiley

Characteristics

- Laboratory hammer mill

Particularities

- Rotation speed of 800 rpm

- Sample size: 50 to 1000 g

- Interchangeable screens (1 mm, 3 mm, 5 mm, 8 mm)

Uses

The sprayer is used on sample biomass matrices devoid of foreign bodies in order to reduce their granulometry to determine their chemical properties.

Technical specs

| Manufacturer | Thomas Scientific |

| Model | 4 |

| Motor | 1.4 kW |

| Scree openings | 0.5, 1 or 2 mm |

Pressurized reactors (600ml)

Characteristics

- Manufacturer Parr

- Model: 600 mL

Particularities

- High pressure and high temperature reactor

Uses

- Hydrothermal biomass liquefaction

- High temperature and high-pressure reaction

Technical specs

| Volume | 600 mL |

| Max temperature | 350 °C |

| Max pressure | 2000 PSI |

| Heating type | Electric heating mantle |

| Cooling | Coil |

| Agitator | Propeller or turbine |

Cryogenic mill

Characteristics

- Energetic cryogenic grinding by impact and friction with a frequency of 30 Hz

Particularities

- Cryogenic grinding, dry or wet, at room temperature

- Screw-on grinding bowls as a guarantee for loss-free grinding

- Clear user interface, 9 storable programs

- Programmable cooling and grinding cycles (10 s to 99 min)

Uses

Cryogenic grinding is used to reduce the size of a matrix composed of heterogeneous materials to determine their chemical properties.

Technical specs

| Manufacturer | Retsch |

| Type: | Cryomill |

| Input material | Hard, semi-hard, soft, brittle, elastic, fibrous |

| Grinding principle | Impact, friction at 196 ˚C |

| Initial particle size | < 8 mm |

| Final particle size | Approx. 5μm |

| Qty supplied / cycle | 20 ml |

| Vibration frequency | 5 – 30 Hz |

Pressurized reactors (20L)

Characteristics

- Manufacturer Parr

- Model: 20L

Particularities

- High pressure and high temperature reactor

Uses

- Hydrothermal biomass liquefaction

- High temperature and high-pressure reaction

Technical specs

| Volume | 20 L |

| Max temperature | 350 °C |

| Max pressure | 1900 PSI |

| Heating type | Electric heating mantle |

| Cooling | Coil |

| Agitator | Propeller or turbine |

Laboratory system for carbonization and activation of biochar

Characteristics

- Tube furnace

Particularities

- Maximum temperature 1100 °C

- Possibility to program several temperature tiers per test

- Precise temperature variation control

- Operation in the absence of oxygen thanks to nitrogen blanketing

- Capture of condensable gases

Uses

Production of different grades of biochar and activated carbon on a laboratory scale.

Technical specs

| Manufacturer | Thermo scientific |

| Model: | Lindberg Blue M Mini-mite |

| Maximum temperature | 1100 °C |

| Maximum quantity | 10 g |

Pellet durability tester

Characteristics

- Predicts the number of fines produced by pellet handling

Particularities

- Variable agitation frequency

- Complies with the standard developed by Kansas State University

Uses

The Pellet Durability Tester identifies the Pellet Durability Index (PDI) to validate the product’s compliance with trade standards.

Technical specs

| Manufacturer | Seedburo equipment company |

| Model | PDT-S |

| Number of compartments | 2 |

| Capacity | 1100 g |

Assembly for autocombustion test

Characteristics

- Assembly designed according to the UN Manual of Tests and Criteria

Particularities

- Autocombustion test at 140 °C, 120 °C and 100 °C

- Temperature variation recording system

Uses

- Classification of self-heating materials

Technical specs

| Standard | 33.4.6. (UN Manual of Tests and Criteria) |

| Sample volume | 100 mm3 and 25mm3 |

| Testing time | 24h |

| Maximum temperature | 200 °C |

| Security | Alarm system and system shutdown at 200 °C |