Our equipment

Biomass characterization and conditioning

The transformation and conversion of residual biomass goes through a pre-treatment sequence designed to homogenize their physico-chemical properties and improve their potential for substitution to virgin source inputs. It is common practice in the industry to encounter a combination of several processes designed to condition forestry, agricultural, municipal and urban residues for any given vocation. Innofibre’s pilot plant houses most of the equipment dedicated to this sector.

Cutting mill

Characteristics

- Cutting mill

Particularities

- Rotor made of tungsten carbide

- Variable speed : 100 to 3000 rpm

- Sample size: 5 liters maximum

- Interchangeable bottom sieves (1 mm, 2 mm, 8 mm)

Uses

Cutting mill is suitable for the grinding of soft, medium-hard, tough, elastic, fibrous, and heterogeneous mixes of products.

Technical specs

| Manufacturer | Retsch |

| Model | SM 300 |

| Motor | 3 kW |

| Sieve sizes | 1, 2 or 8 mm |

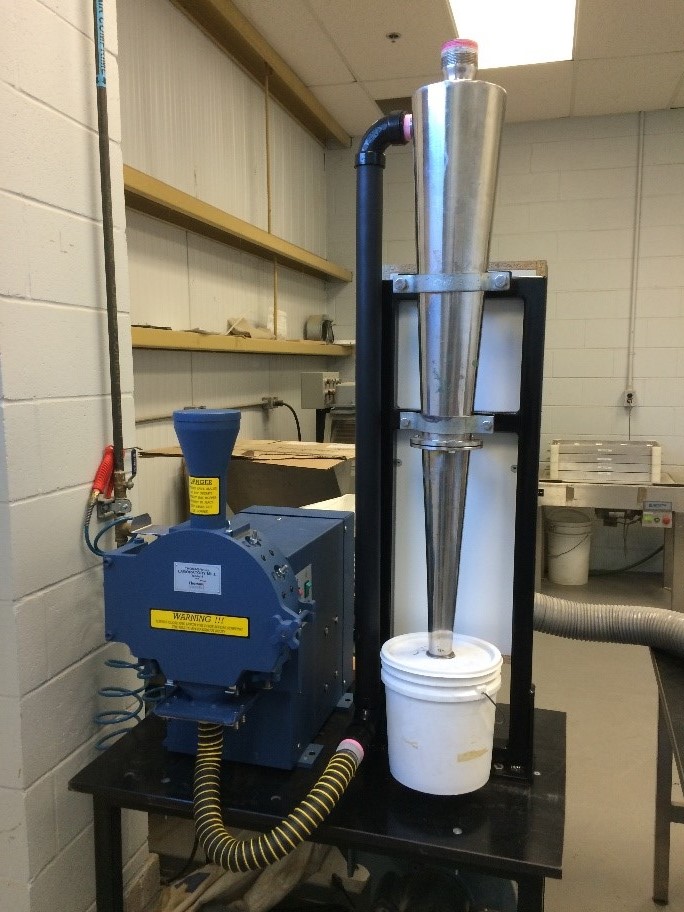

Pulveriser Thomas Wiley

Characteristics

- Laboratory hammer mill

Particularities

- Rotation speed of 800 rpm

- Sample size: 50 to 1000 g

- Interchangeable screens (1 mm, 3 mm, 5 mm, 8 mm)

Uses

The sprayer is used on sample biomass matrices devoid of foreign bodies in order to reduce their granulometry to determine their chemical properties.

Technical specs

| Manufacturer | Thomas Scientific |

| Model | 4 |

| Motor | 1.4 kW |

| Scree openings | 0.5, 1 or 2 mm |

Cryogenic mill

Characteristics

- Energetic cryogenic grinding by impact and friction with a frequency of 30 Hz

Particularities

- Cryogenic grinding, dry or wet, at room temperature

- Screw-on grinding bowls as a guarantee for loss-free grinding

- Clear user interface, 9 storable programs

- Programmable cooling and grinding cycles (10 s to 99 min)

Uses

Cryogenic grinding is used to reduce the size of a matrix composed of heterogeneous materials to determine their chemical properties.

Technical specs

| Manufacturer | Retsch |

| Type: | Cryomill |

| Input material | Hard, semi-hard, soft, brittle, elastic, fibrous |

| Grinding principle | Impact, friction at 196 ˚C |

| Initial particle size | < 8 mm |

| Final particle size | Approx. 5μm |

| Qty supplied / cycle | 20 ml |

| Vibration frequency | 5 – 30 Hz |

Pellet durability tester

Characteristics

- Predicts the number of fines produced by pellet handling

Particularities

- Variable agitation frequency

- Complies with the standard developed by Kansas State University

Uses

The Pellet Durability Tester identifies the Pellet Durability Index (PDI) to validate the product’s compliance with trade standards.

Technical specs

| Manufacturer | Seedburo equipment company |

| Model | PDT-S |

| Number of compartments | 2 |

| Capacity | 1100 g |