cellulosic packaging | Pulp and Paper

LBJ-TM12+

Characteristics

Manufacturer: Techman

Model: TM 12

Uses

The robotic arm is used for spraying. It can be used in automatic mode or used in conventional mode on a conveyor.

Technical specs

| Articulations |

6 |

| Range |

1300 mm |

| Speed |

0 – 250 mm/s |

| Mode |

Collaborative |

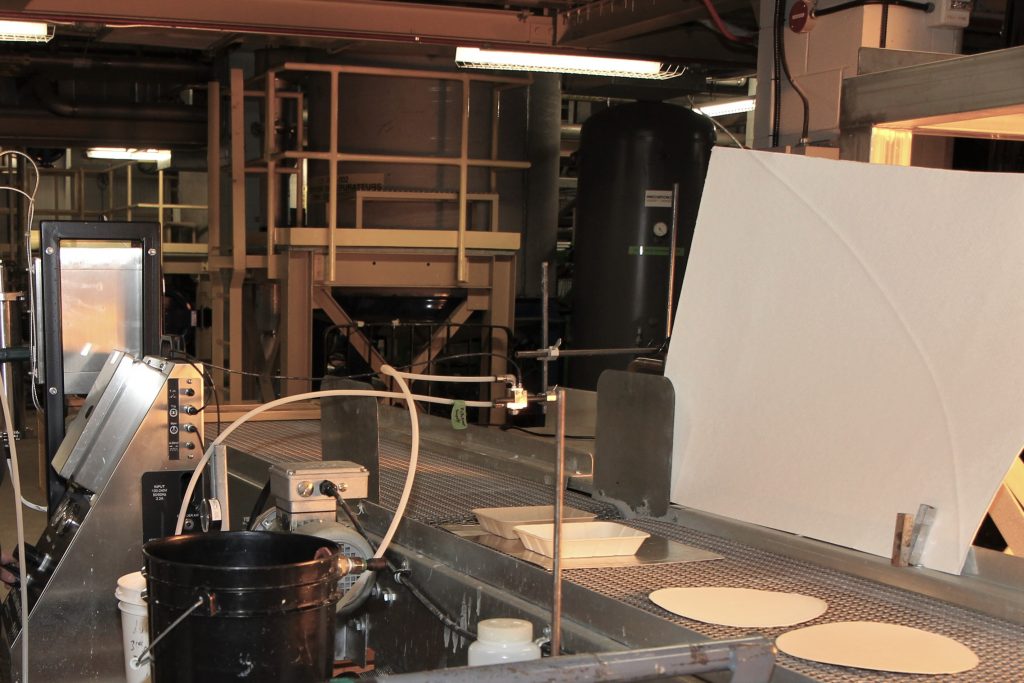

Thermoforming system

Characteristics

- MSI PME, MecSmart

- Model: TF-45

Particularities

- System consisting of a forming mould, a transfer mould and two drying press moulds.

- Adjustment of the thickness of the parts by distance control.

- System for heating the pulp.

- Easily interchangeable aluminum mould to adapt to new pieces.

- Possibility to integrate the resin mould technology.

- Possibility of adding additives to the pulp by means of a dosage system

Uses

Production of Type 2 cellulosic thermoformed parts (without pressing) or Type 3 (with pressing).

Technical specs

| Max Product Size L x W x H |

1524 mm x 533 mm x 76.2 mm (60 inch x 21 inch x 3 inch) |

| Platen configuration |

5 individual platens to manufacture up to 5 different products of 304 mm x 533 mm |

| Max Capacity |

45 kg per hour dry weight |

| Min pulp quantity |

4 kg dry weight |

| Drops per minutes |

2 pending product thickness and geometry |

| Moulding Tank Capacity |

330 L – Max Capacity of 756 L |

| Vacuum System |

685 mmHg adjustable |

| Moulding System |

Servo driven rotary head, vacuum system |

| Blow off System |

6.9 barg and 2.8-4.2 m3/min adjustable |

| Transfer System |

Servo driven y-axis and z-axis programmable, vacuum system, blow off system |

| Heating System |

Multi-zoned and adjustable, upper and lower platens heating, upper and lower tools heating |

| Thermoforming System |

Servo driven vertical z-axis multi positions, heating system, vacuum system, blow off system |

| Additive System |

4 reservoirs with individual pumps (3 low dose materials and 1 for colour) |

| Die Wash System |

Tooling Die Wash System at low and high pressure (33 barg) |

| Stacking and Unloading System |

Integrated Stacking System and Transfer Conveyor to the operator for packing |

Blade/Rod Coater

Technical specs

| Manufacturer |

Jagenberg/BMB |

| Model |

Blade/Barflex |

| Coating Weight |

4-20 g/m2 |

| Maximum Solid Content |

68 % |

| Viscosity |

300-2000 cPs |

Chip screen

Technical specs

| Manufacturer |

Rader |

| Model |

M-2215 |

| Type |

Disks |

| Thickeness fractions |

>= 8 mm, 8-6 mm, 6-4 mm, 4-2 mm, <= 2mm |

On-line chemical addition

Technical specs

| Number of dosing pumps |

4 |

| Type of pumps |

Progressive cavity |

| Type of control |

Flow or ratio |

| Remotely monitored variables |

Level and flow |

| Injection points available |

Several |

Chip washer

Technical specs

| Manufacturer |

Kvaerner Hymac |

| Model |

LC-20 |

| Type |

Rotating drum and shower |

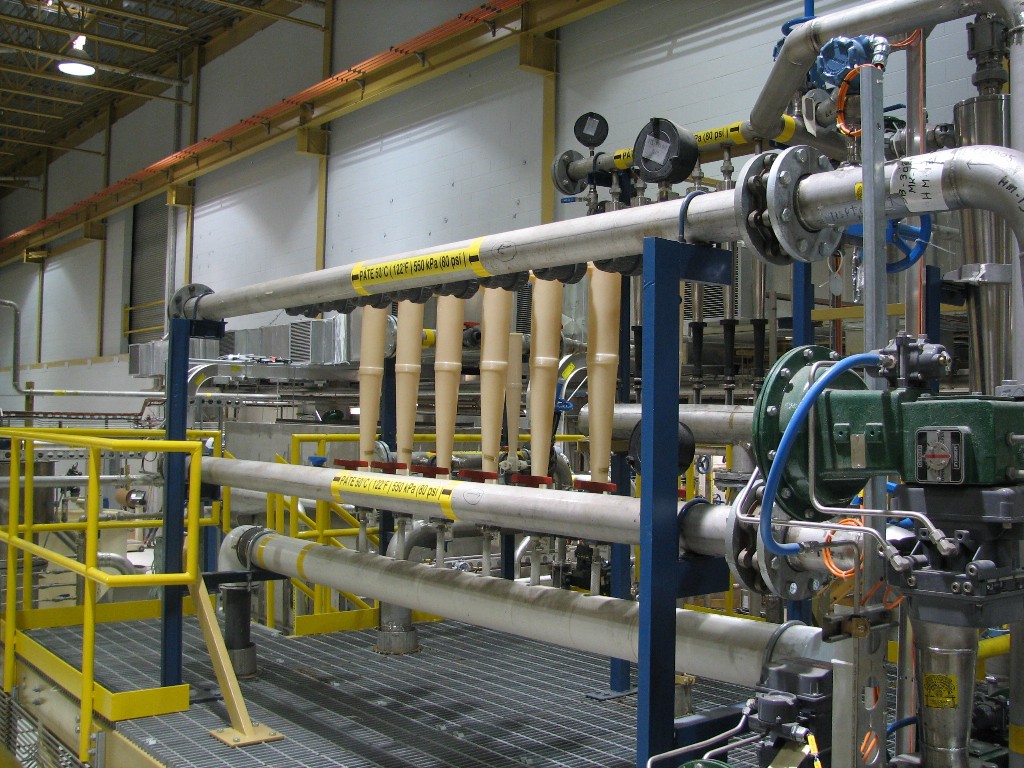

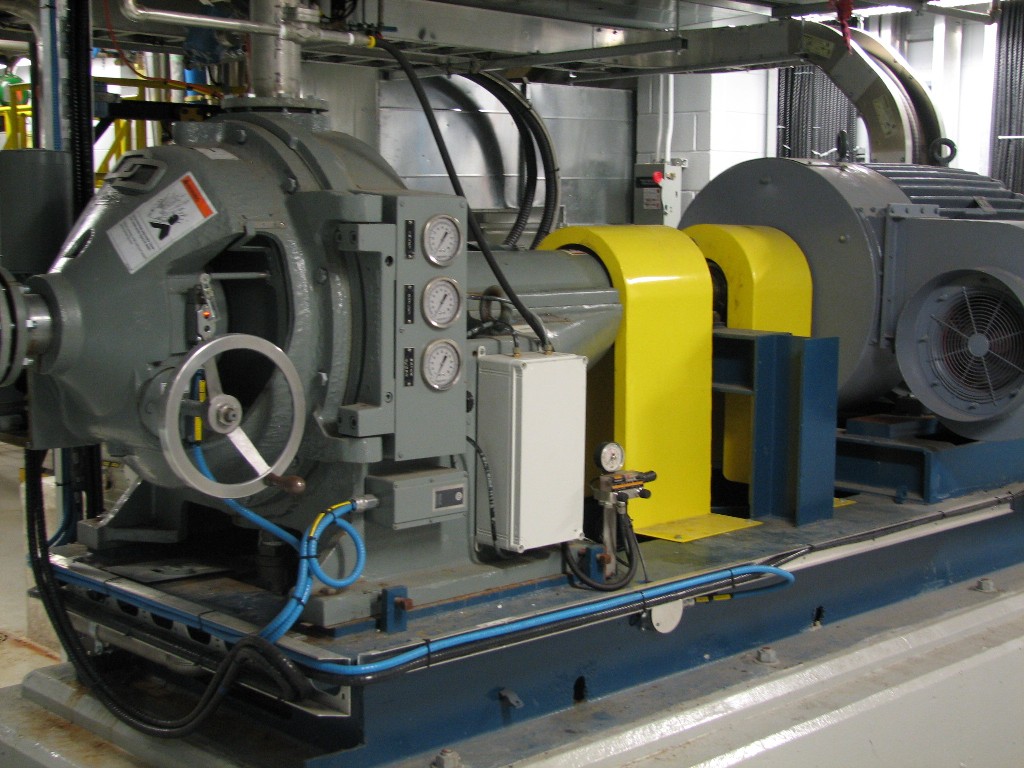

Approach system

Technical specs

| Machine chest capacity (m3) |

70 |

| Number of storage tanks |

2 |

| Storage tank capacity (m3) |

25 |

| Total pulp storage capacity (m3) |

120 |

| Headbox screen |

Selectifier 24-P |

| Dilution water screen |

Selectifier 12-P |

| Cleaner model |

Cleanpac 700 |

| Number of cleaners available (1st stage) |

20 |

| Number of stage |

5 |

Gravure Coater

Technical specs

| Manufacturer |

Jagenberg/BMB |

| Model |

Variogravure |

| Coating Weight |

7.5-10.5 g/m2 |

| Maximum Solid Content |

55 % |

| Maximum Viscosity |

200 cPs |

| Applicator Roll line spacing |

33 rows/cm @ 45° |

Headbox

Technical specs

| Model |

BTF |

| Type |

Dilution |

| Number of dilution zones |

5 |

| Oscillating breast roll adjustment |

Speed & frequency |

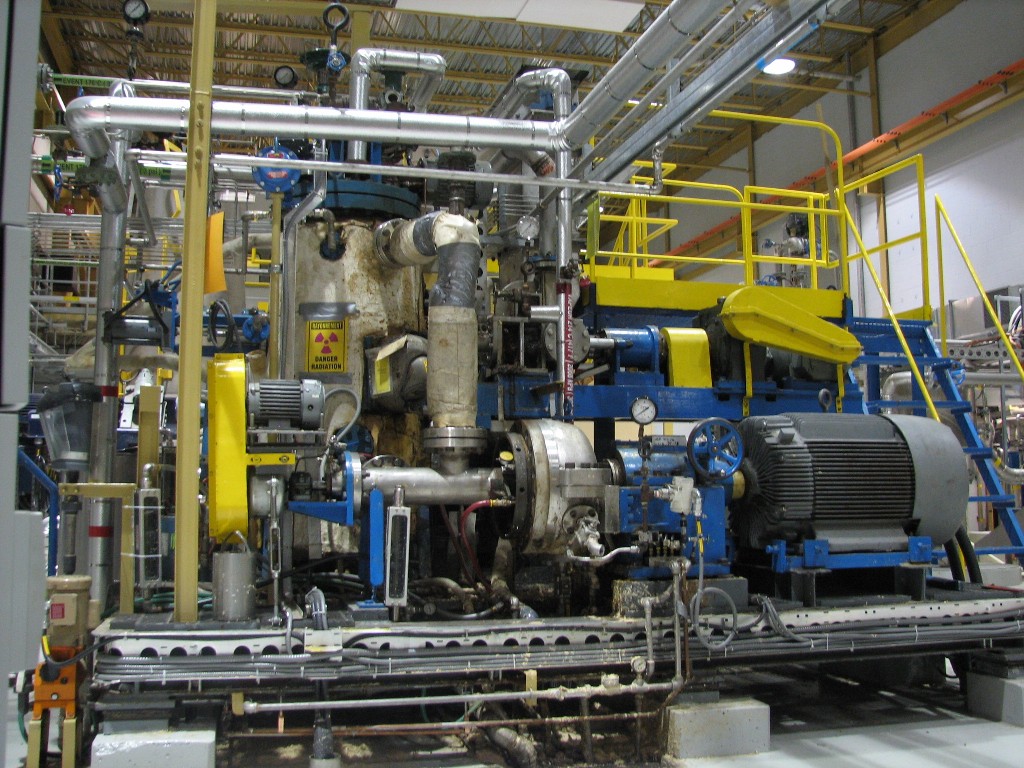

Atmospheric impregnation system

Technical specs

| Manufacturer |

Kvaerner Hymac |

| Capacity |

10-15 tm/j |

| Pre-heating bin |

APS-60, 3.7 m3 |

| Side feeder |

SF-07, 180 mm dia. |

| Plug screw feedeer |

PSF-0740, 180 mm dia., ratio 4@1, 45 kW |

| Imprégnator |

AVIS-1008, 240 mm dia., 2 vertical screws |

Coater/Laminator

Technical specs

| Manufacturer |

Danson |

| Model |

Hartig |

| Adhesion Treatment |

Corona (Pillar Corp.) 4.2 kVA |

| Chill Roll |

597 mm dia./Matte Surface |

| Secondary Unwind Stand |

457 mm roll on 76.2 mm Core |

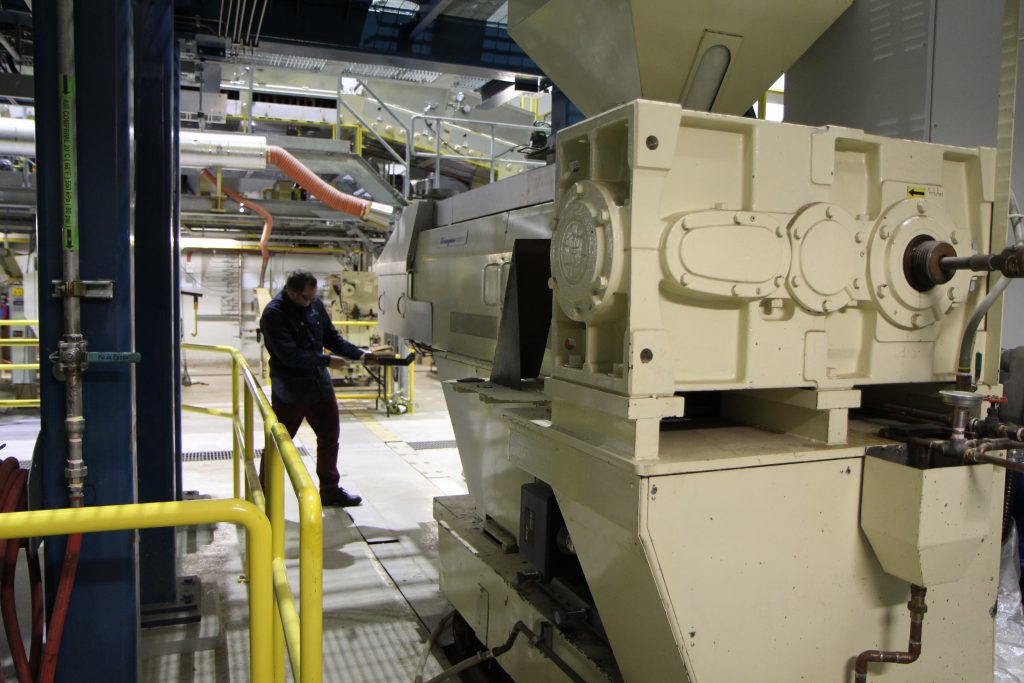

Extruder

Technical specs

| Manufacturer |

Brampton Engineering |

| Model |

350-30AC |

| Power – motor |

75 kW |

| Power – heating |

37.4 kW |

| Number of heating zones (barrel) |

6 |

| Number of heating zones (die) |

3 |

| Number of heating zones (die lip) |

1 |

| Die manufacturer |

Egan “Series 32” |

| Slot width |

760 mm |

| Screw diameter |

89 mm |

| L/D Screw Ratio |

30:1 |

| Maximum Temperature |

480°C |

| Extrusion Capacity (LDPE) |

205 kg/h |

Formation table

Technical specs

| Table length (m) |

21 |

| Number of top formers available |

2 |

| Former type |

“V” et “C” |

| Vacuum box number |

18 |

| Vacuum box flow measurment |

V-notch |

Refining system

Technical specs

| Manufacturer |

Metso |

| Capacity |

0.65-3.3 tm/j |

| Pre-heating bin |

0.14 m3 |

| Plug scew feeder |

PR 4, 100 mm dia., ratio 2@1, 7.5 kW |

| Pre-heater |

0.11 m3, Pmax 1700 kPag, Tmax 207°C |

| Disk primary refiner |

CD-300, 150 kW, variable speed |

| Steam separator |

Pmax 1200 kPag, Tmax 190°C |

| Interstage bin |

0.7 m3 |

| Disk secondary refiner |

CD-300, 150 kW, variable speed |

Presses

Technical specs

| First press type |

Bi-Nip |

| First press load (kN/m) |

100 |

| Second press type |

Jumbo |

| Second press maximum load (kN/m) |

350 |

| Third press type |

Extended nip |

| Third press maximum load (kN/m) |

1000 |

| Number of different configurations |

8 |

| Availability of wet sheet reeling |

Yes |

Moisturizing Unit

Technical specs

| Manufacturer |

Coating Moisturizing System |

| Model |

CM-203 |

| Coating Weight |

0.4-50 g/m2 |

| Maximum Solid Content |

65 % |

Static reactor

Technical specs

| Manufacturer |

– |

| Model |

Vertical Cylinder |

| Volume |

2 m3 |

| Maximum pressure |

1720 kPag |

| Maximum temperature |

208°C |

Infrared Dryer

Technical specs

| Manufacturer |

Krieger |

| Energy Source |

Natural gas |

| Number of Rows |

4 |

| Number of Emitters |

5 per row |

| Power |

32 kW/row |

Dryers

Technical specs

| Number of sections |

3 |

| Number of cylinders – first section |

4 |

| Number of cylinders – second section |

12 |

| Number of cylinders – third section |

12 |

| Drying cylinder diameter (m) |

1.52 |

| Steam flowrate measurement |

Yes |

| Condensate flowrate measurement |

Yes |

| Hood type |

Fully closed |

| Siphon type |

Fixed |

| Tail threading system manufacturer |

Wespatt |

| Type of tail threading system |

Rope |

Hot Air Dryer

Technical specs

| Manufacturer |

BMB |

| Number of hoods |

3 |

| Maximum Air Temperature |

190°C |

| Maximum Air Speed |

50 m/s |

| Number of Nozzles |

25 nozzles/hood |

High consistency pulper

Technical specs

| Manufacturer |

Kvaerner Hymac |

| Model |

4.2 HC 43 |

| Volume |

4.2 m3 , dilution up to 16 m3 |

| Capacity |

600 kg sec |

| Consistency |

12-15% |

| Motor |

112 kW |

| Rotor speed |

232 rpm |

| Extraction plate |

16 mm holes, 22.7% open area |

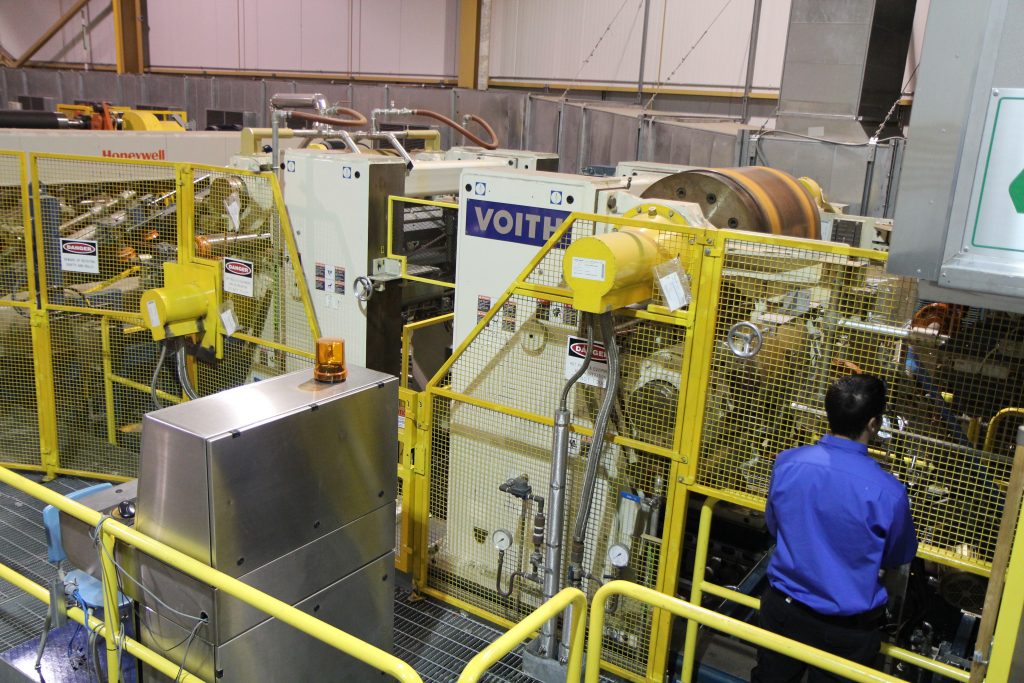

Calender

Technical specs

| Manufacturer |

Voith |

| Model |

Ecosoft |

| Type of calender |

Soft nip |

| Number of stacks |

2 |

| Maximum speed (m/min) |

1500 |

| Maximum load (kN/m) |

500 |

| Maximum temperature (°C) |

150 |

| Steam shower position |

On each nip |

| Type of covers |

Several available |

Discharge/latency tank

Technical specs

| Volume |

35 m3 |

| Consistency |

Up to 5% |

| Heating |

Direct and indirect |

| Agitator |

37 kW, constant speed |

On-line Measurement System

Technical specs

| Manufacturer |

Honeywell |

| Model |

ProLine |

| Number of Scanners |

2 |

| On-line Measurements |

Basis weight, moisture |

Scanner

Technical specs

| Manufacturer |

Honeywell |

| Model |

Da Vinci |

| Number of sensors |

8 |

| Sensor types |

- Basis weight

- Moisture

- Caliper

- Gloss (both sides)

- Color

- Brightness

- Opacity

- Formation

|

| Automatically control variables |

Basis weight, moisture |

Reel

Technical specs

| Manufacturer |

GL&V |

| Type of reel |

With primary and secondary arms |

| Maximum reel diameter (mm) |

2000 |

| Sheet transfer |

With air jet |

Pressurize screen

Technical specs

| Manufacturer |

GL&V |

| Model |

M-18 |

| Dimension |

457 mm dia. |

| Flow |

1000-6000 LPM |

| Consistency |

0.6-2.5% |

| Motor |

93 kW speed |

| Baskets et rotors |

Several available |

Supercalender

Technical specs

| Manufacturer |

B.F. Perkins |

| Type |

Off line |

| Number of nips |

4 |

| Steam shower |

1 |

| Maximum speed |

183 m/min (600 pi/min) |

| Sheet maximum width |

63.5 cm (25 po) |

| Sheet nominal width |

61 cm (24 po) |

| Total load |

4.5 – 14.5 tm |

| Linear pressure |

72 – 233 kN/m (417 – 1300 pli) |

| Maximum roll diameter |

50 cm (20 po) |

Winder

Technical specs

| Manufacturer |

GL&V |

| Type of winder |

Single drum |

| Jumbo roll maximum diameter (mm) |

2032 |

| Paper roll maximum diameter (mm) |

1220 |

| Maximum speed (mm) |

1000 |

| Core support type |

Air shaft |

| Core diameter (mm) |

102 |

Flotation cells

Technical specs

| Manufacturer |

Kadant (Black Clawson) |

| Model |

IIM-BC Flotator 5 |

| Volume |

7 m3 |

| Flow |

350-950 LPM |

| Consistency |

0.8-1.2% |

| Ratio air/pulp |

5-10 |

Lightweight contaminant hydrocyclones

Technical specs

| Manufacturer |

Kadant (Black Clawson) |

| Model – stage 1 |

X-clone (7) |

| Model – stage 2 |

X-clone (1) |

| Dimension |

75 mm dia. |

| Flow |

1200-1600 LPM |

| Consistency |

0.9-1.0% |

On-line historian

Technical specs

| Manufacturer |

OSIsoft |

| Software |

PI |

| Number of recorded variables (pilot plant total) |

>= 1000 |

| Data acquisition frequency (s) |

1-60 |

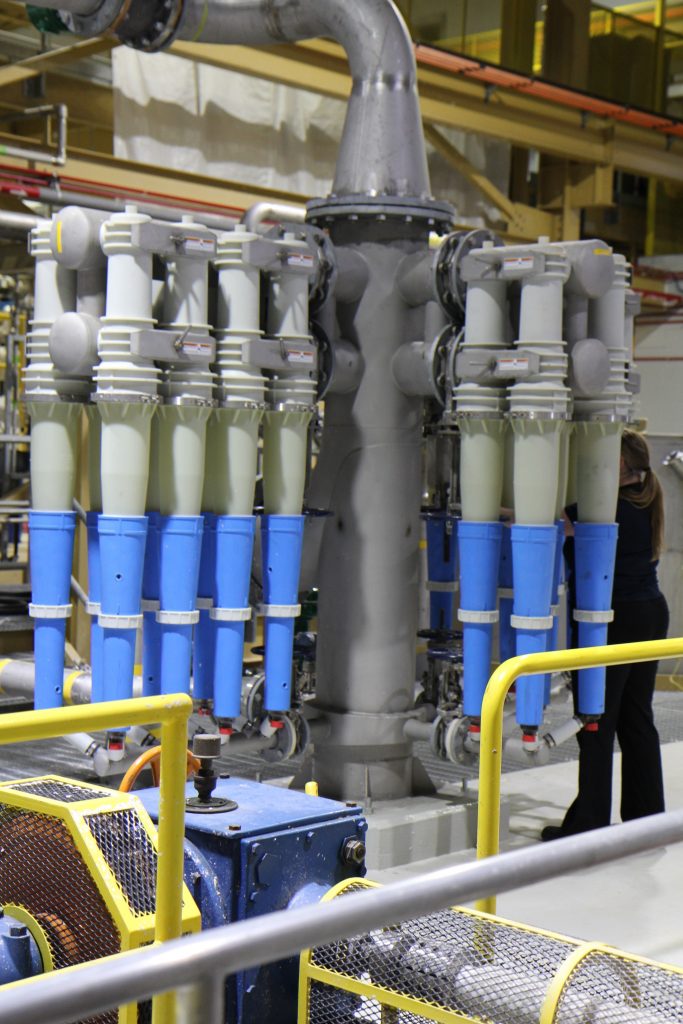

Conventional hydrocyclones/Forward cleaners

Technical specs

| Manufacturer |

Kvaerner Hymac |

| Model – stage 1 |

HY-200EH 2.0 (3) ou HY-80X (15) |

| Model – stage 2 |

HY-200EH 2.0 (1) ou HY-80X (6) |

| Model – stage 3 |

HY-100EH (1) |

| Model – stage 4 |

HY-90EH (1) with or without elutriation |

| Dimension |

80-200 mm dia. |

| Flow |

1500-1700 LPM |

| Consistency |

0.45-1.2% |

On-line surface application system

Technical specs

| Manufacturer |

GL&V |

| Model |

Hydra Sizer |

High-speed camera

Characteristics

| Manufacturier |

PaperTech |

| Modèle |

TotalVisions System Platform |

High density hydrocyclone

Technical specs

| Manufacturer |

Kvaerner Hymac |

| Model |

HY-300HD 2.5 |

| Dimension |

300 mm dia. |

| Flow |

650-850 LPM |

| Consistency |

3-4% |

Screening system

Technical specs

| Manufacturer |

Kadant (Black Clawson) |

| Model – P1 |

Selectifier 8P |

| Model – P2 |

Mini-Screen MS-50 |

| Model – S |

Mini-Screen MS-50 |

| Dimension |

405 (P1) et 410 (P2, S) mm dia. |

| Flow |

500-2000 LPM |

| Consistency |

0.6-2.5% |

| Motor |

22 kW, (P1 at variable speed) |

| Baskets et rotors |

Several available |

Decker/Slusher

Technical specs

| Manufacturer |

Kvaerner Hymac |

| Model |

with or without couch roll |

| Dimension |

1.2 m dia. X 1.2 m |

| Flow |

650-2000 LPM |

| Consistency – inlet |

0.5-1.2% |

| Consistency – outlet |

4-7% |

| Top wire |

10 mesh in stainless steel |

| Bottom wire |

40 mesh in stainless steel |

| Motor |

3.7 kW at variable speed |

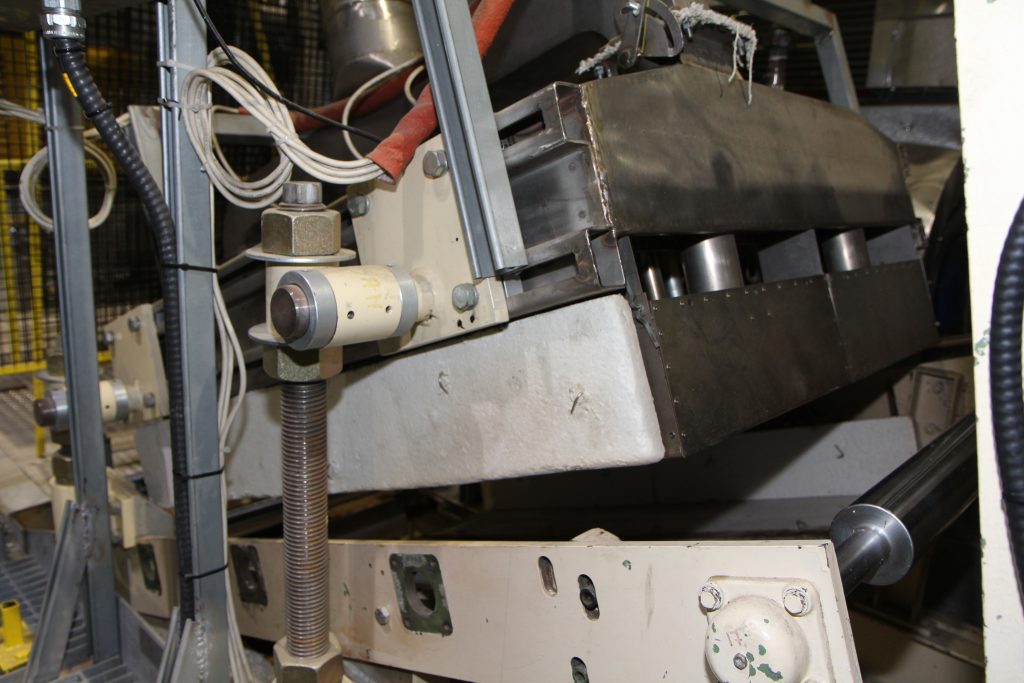

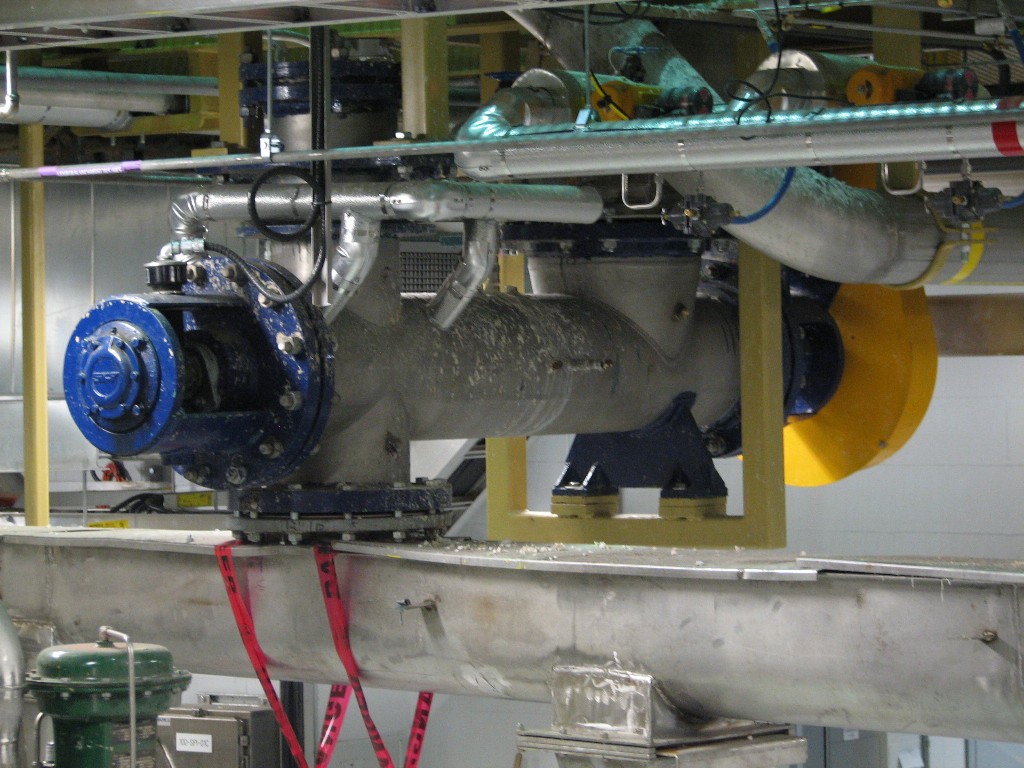

Screw press

Technical specs

| Manufacturer |

Thune (Voith) |

| Model |

SP-23 |

| Dimension |

240 mm dia. |

| Flow |

150-400 LPM |

| Consistency – inlet |

3-5% |

| Consistency – outlet |

25-35% |

| Motor |

Hydraulic, 0-60 t/min |

| Basket |

1.2 mm dia. holes, open area 22.5% |

High consistency mixer

Technical specs

| Manufacturer |

Kvaerner Hymac |

| Model |

HSM-12 |

| Dimension |

300 mm dia. |

| Capacity |

10-15 tm/jour |

| Consistency |

25-35% |

| Injection |

Vapeur et liqueur de blanchiment |

Side hill screen

Technical specs

| Manufacturer |

Sweco |

| Model |

SV4YA |

| Dimension |

1270 mm X 1170 mm |

| Flow |

400-500 LPM |

| Consistency – inlet |

0.5-1.2% |

| Consistency – outlet |

3-5% |

| Slots |

0.51 mm |

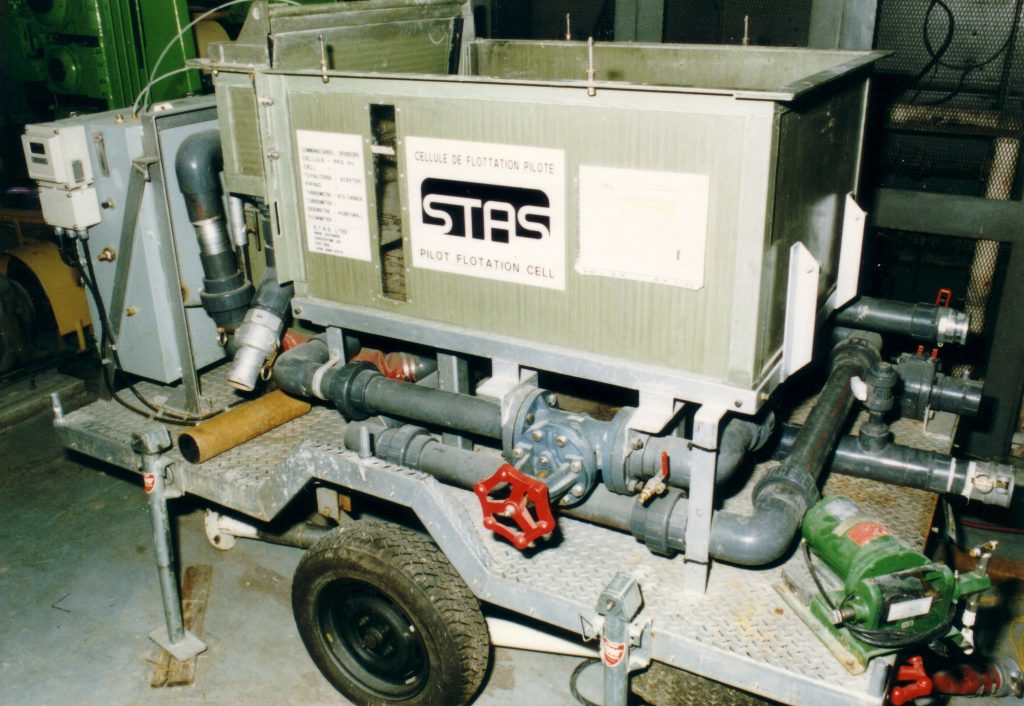

Dissolved air flotation cell

Technical specs

| Manufacturer |

STAS |

| Model |

Mobil unit on a trailer |

| Volume |

0.54 m3 |

| Flow |

115 LPM |

| Aeration |

2.5-5.0 LPM |

Bleaching system

Technical specs

| Manufacturer |

Valmet |

| Volume – bin |

0.6 m3 |

| Mixer |

Consistency 15-40% |

| Agitated reactor |

0.74 m3, Pmax 800 kPag, Tmax 175°C |

| Injection |

Steam, bleaching liquor |

Hydrocyclone test bench

Technical specs

| Models Kvaerner Hymac |

HY-200EH 2.0, HY-150, HY-100EH, HY-80X |

| Models GL&V (Celleco) |

Cleanpac 250 LWR, 270, 350 |

| Models GL&V (Beloit) |

Posiflow, Uniflow |

| Models Kadant (Noss) |

AM80, BM80 |

| Dimension |

80-200 mm dia. |

| Flow |

50-750 LPM |

| Consistency |

0.45-1.2% |

Low consistency disk refiner

Technical specs

| Manufacturer |

GL&V (Beloit) |

| Model |

DD-4000 (single disk version) |

| Disk diameter |

500 ou 600 mm |

| Flow |

125-1200 LPM |

| Consistency |

2-6% |

| Motor |

335 kW, 1200 t/min,variable speed |

| Disk patterns |

Several available |

3D Printer

Characteristics

- Manufacturer: Stratasys

- Model: Fortus 450 MC

Particularities

Several types of resin: (ABS-M30, ASA, PC, FDM nylon12, Ultem 1010, Ultem 9085).

Uses

- Production of moulds for the cellulosic moulding process

Technical specs

| Size of parts |

16”x14”x16” |

| Layer thickness |

- 0.330 mm (0.013 in): ABS-M30, ABS-M30i, ASA, FDM Nylon 12, PC, ULTEM™

- 0.254 mm (0.010 in): ABS, ASA, FDM Nylon 12, PC, ULTEM™

- 0.178 mm (0.007 in): ABS-ESD7, ABS-M30i, ASA, FDM Nylon 12, PC

- 0.127 mm (0.005 in): ABS-M30, ABS-M30i, ASA, PC

|

Spraying System

Characteristics

- Manufacturer: Spraying System

- Model: 1550+ autojet modular spray system

Particularities

- Spraying controller

- Double diaphragm pneumatic pump

- Air input regulator and filter

- Liquid pressure regulator, manometer, and output filter

- Recirculation and bypass gate valves

- Pulsajet nozzles

- HD15 heating system

Uses

Surface spray coating

Technical specs

| Nozzle opening |

5 to 100% |

| Fixed conveyor-mounted system (15–60 ft/min) |

Low consistency conical refiner

Technical specs

| Manufacturer |

Valmet |

| Model |

RF-0 conical |

| Flow |

90-870 LPM |

| Consistency |

2-6% |

| Motor |

150 kW, 1800 t/min, variable speed |

| Cone patterns |

SM, SF, LF, LC |

Tornado pulper

Technical specs

| High consistency pulper |

| Manufacturer |

Bolton-Emerson |

| Model |

Tornado 24 |

| Dimension |

3 m3, dilution jusqu’à 8000 L |

| Capacity |

150 kg sec |

| Consistency |

3-6 % |

| Motor |

150 kW |

| Rotor speed |

Variable (max : 650 t/min) |

Twin-wire press

Technical specs

| Twin-wire press |

| Manufacturer |

Press Technologies |

| Model |

0.5M LP |

| Width |

457 mm |

| Capacity |

150-400 L/min |

| Consistency |

Entrée : 1-5 %

Sortie : 25-40 % |

| Density |

1000-3000 g/m2 |

| Max speed |

13.4 m/min |