Forests and fields for paper and cardboard

26 July 2024

Author: Martin Dubé, teacher at Cégep de Trois-Rivières and researcher at Innofibre.

In several regions of the world, the pulp and paper industry has always been closely associated with wood, forests and sawmills. However, there are many other sources of fiber and these could play an increasingly important role in the future.

When old know-how becomes innovation

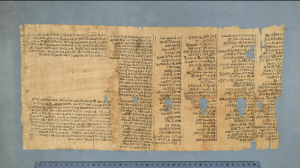

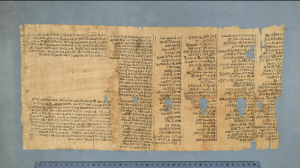

Ancient paper production was already based on non-wood fibers, such as papyrus or cotton. Several specialized paper products already use fibers from bagasse (fibrous residues from sugar cane milling) or bamboo. In Eastern North America, it would be possible to use the residues of cereal crops which generate significant volumes of biomass (approximately 2 million metric tons (MTM) per year in the sole province of Québec, in Canada). In addition, new emerging crops, such as hemp and cannabis, are generating an increasing amount of residues.

Figure 1 – Papyrus from the Roman or Ptolemaic period, 23.5 cm high and 49 cm long. The document is a hymn from the ritual text entitled: Book of the Feasts of Osiris in the Month of Khoiak; Litanies of Sokar. Collection of the Louvre Museum, Department of Egyptian Antiquities.

Credit: https://collections.louvre.fr

Great potential and major boundaries

Several technical and logistical problems still need to be solved, and currently, the profusion of wood chips available on the market does not encourage the research and use of agricultural fibres for pulp and paper.

As the name implies, non-wood fibers contain less lignin than traditional lignocellulosic fibers from hardwoods or softwoods. Thus, they offer a certain advantage in terms of pulping. On the other hand, like any other residual biomass, the low density of the residues imposes significant logistical constraints, including transportation, storage and, in some cases, preservation costs. Although typical pulping processes (mechanical, semi-chemical or chemical) are quite adaptable to agricultural residues, the large volumes required for paper production significantly increase transportation costs. While all territories are trying to develop solutions regarding these constraints, for several regions, this represents a particularly important challenge due to the low concentration of agricultural production on its territory. Howevwe, it can be a significant advantage to other regions such as the Canadian or American prairies.

Equipment adapted to territorial realities

In this respect, it is interesting to explore dry defibration processes (grinding to obtain coarse fibers) or chemical-thermomechanical pulping processes using twin-screw extruders (simultaneous cooking and refining steps). These processes could offer economically viable solutions, as it is important to adapt the fiber’s processing method according to the location of the different biomass deposits. Consideration must also be given to whether the biobased material should be processed before or after transportation.

Figure 2 – The twin screw extruder which allows simultaneous cooking and refining steps

In paper and board, fibers from cereal crops are similar in length to hardwood fibers and can be used as supplementary fibers. Hemp or flax fibers, which are much longer, can be used as reinforcing fibers, but these fibers must first be refined. This can be accomplished by a “Tornado” type pulper/refiner that will cut the fibers at the same time as it refines them by fibrillating and opening the structure of the fiber. These long fibers from agricultural biomass also have great potential for use in thermoformed or non-woven products.

Figure 3 – The “Tornado” type pulper/refiner that simultaneously cuts and refines the long fibers.

And even more challenges

Another major challenge is that, in general, agricultural fibers have lower drainage properties than other fibers, thus reducing mill production capacity. To allow for pulp drainage in the wet end of the paper machine, the production speed of the machine could be reduced. This would have a major impact on the production capacity of a mill. Innofibre is studying how to adapt equipment and processes to allow the use of these fibers while maintaining an interesting level of productivity.

To conclude, agricultural residues can provide an alternative source of fiber, but it is important to realize that there are no “one size fits all” situations and that each type of residue requires a unique set of technical, logistical and marketing solutions. The Innofibre team is working to develop innovative processes that will allow the valorization of this abundant biomass into paper, cardboard, and other cellulosic products with multiple properties.

Figure 4 – Cannabis biomass. Left: green branches of cannabis plants, 1-3 days after harvest. Right: sun-dried branches of cannabis plants, 2-3 months after harvest.