Lignin: A Revenue Opportunity for the Paper Industry?

26 July 2024

By Michel Labbé, researcher at Innofibre, and Mathieu Germain, teacher and researcher at Innofibre

Despite its potential as an added-value product for pulp and paper mills, each year several thousand tons of lignin end up in the mills’ black liquor, which is a mixture containing cooking chemicals and residual wood material that remains after pulping. Under current practices, most of this lignin is burnt in recovery boilers, which allows for the regeneration of cooking chemicals and the production of energy for the mill. To increase profit margins, certain mills are being equipped with conversion units, that convert lignin into added-value products. Despite the challenges involved in these processes, several factors contribute to significantly expanding the marketing of these products, such as:

-

The closure of several chemical pulp mills has led to a market demand for applications that are known.

-

Biorefinery is a result of the industry’s desire to find an alternative solution to using fossil fuels. The new technology of producing alcohol using sugars seems economically fragile and profits could be increased by using residual lignin.

-

Preoccupations concerning sustainable development place lignin as a base product of choice for green chemistry and for ‘’green marketing’’.

-

Recent developments in technology have shown that lignin can be used in the manufacturing of various bioproducts, such as carbon fibers, adhesives, or insulating foams.

To allow for a smooth transition, mills will continue to use lignin for producing energy, while gradually putting in place strategies for lignin conversion into added-value products. This is an excellent path to follow to reduce the risks associated with market development.

What are the Applications for Lignin?

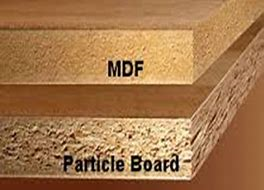

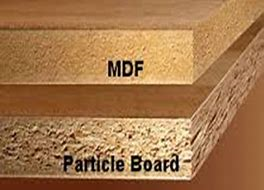

As a polymeric surfactant, lignin is used as a dispersing agent for concrete, ceramics, carbon black, gypsum boards, as emulsion stabilizers for waxes and asphalt, or as a grinding aid for minerals. Its binding properties make it a sought-after bioproduct for making fertilizer pellets or animal feed. In collaboration with various partners, Innofibre is currently working on ways to modify lignin so that it will be compatible to use in various sought-out applications. Innofibre also provides its expertise in the formulation of lignin-based phenolic resin, melamine, polyurethane, and urea formaldehyde The images below provide a few examples of ways to use lignin:

Figure 1 : Adhesive for wood panels.

Figure 2 : Insulating foam and how it is applied in the making of insulating panels.

Figure 3 : Image of a lignin block.

Despite its potential as an added-value product for pulp and paper mills, each year several thousand tons of lignin end up in the mills’ black liquor, which is a mixture containing cooking chemicals and residual wood material that remains after pulping. Under current practices, most of this lignin is burnt in recovery boilers, which allows for the regeneration of cooking chemicals and the production of energy for the mill. To increase profit margins, certain mills are being equipped with conversion units, that convert lignin into added-value products. Despite the challenges involved in these processes, several factors contribute to significantly expanding the marketing of these products, such as:

-

The closure of several chemical pulp mills has led to a market demand for applications that are known.

-

Biorefinery is a result of the industry’s desire to find an alternative solution to using fossil fuels. The new technology of producing alcohol using sugars seems economically fragile and profits could be increased by using residual lignin.

-

Preoccupations concerning sustainable development place lignin as a base product of choice for green chemistry and for ‘’green marketing’’.

-

Recent developments in technology have shown that lignin can be used in the manufacturing of various bioproducts, such as carbon fibers, adhesives, or insulating foams.

To allow for a smooth transition, mills will continue to use lignin for producing energy, while gradually putting in place strategies for lignin conversion into added-value products. This is an excellent path to follow to reduce the risks associated with market development.

What are the Applications for Lignin?

As a polymeric surfactant, lignin is used as a dispersing agent for concrete, ceramics, carbon black, gypsum boards, as emulsion stabilizers for waxes and asphalt, or as a grinding aid for minerals. Its binding properties make it a sought-after bioproduct for making fertilizer pellets or animal feed. In collaboration with various partners, Innofibre is currently working on ways to modify lignin so that it will be compatible to use in various sought-out applications. Innofibre also provides its expertise in the formulation of lignin-based phenolic resin, melamine, polyurethane, and urea formaldehyde The images below provide a few examples of ways to use lignin: