The potential of Canadian forest tree bark

26 July 2024

By: Annabelle St-Pierre, Researcher at the Innofibre Research Centre

The lumber industry is a key player in Canada’s economy owing to its large wood production, which accounts for several millions of dry tons of residual bark each year. This underexploited co-product is mainly sent to landfills or to combined heat and power plants to be converted into energy. But could there be other uses for this valuable residue?

Using Bark for our Protection

Bark is to trees as what skin is to humans; that is, a protective barrier against invaders and harsh environmental conditions. This tree ‘skin’ contains large quantities of specialized compounds, some of which have biological activities that can protect against pathogens, insects, sunlight, etc. A further look into the nature and abundance of these compounds shows that they vary according to species, age, and growing conditions of the trees. Although fully understanding bark molecular composition is complex, there is no doubt as to it being a highly interesting biomass to study based on its contents.

Natural Molecules with Great Potential

The Innofibre team has been working on the valorization of residual bark for several years, exploring ways to develop ingredients with high concentrations of bioactive molecules that could be incorporated in the making of various products. Our research has shown that the molecules obtained from bark biomass have important antimicrobial and antioxidative properties. These are particularly interesting for industries related to the sanitary, therapeutic, food, and cosmetic fields, just to name a few, where they could become key ingredients in the making of all sorts of products. Their appeal as an antimicrobial agent applies to several products that are currently in high demand, such as sanitizers and surface disinfectants, anti-septic agents, hand soaps, and preservatives found in food, cosmetic, and body and skin care products. Their antimicrobial activity is also highly attractive for the food storage industry, where they could be incorporated in the making of wrappings and containers allowing to substantially extend the shelf life of our food. Furthermore, these natural antimicrobial agents found within bark molecules could be a natural replacement solution to chemical biofongicides currently used to protect plants from diseases in crop cultures. With respect to their antioxidant properties, these compounds could be used as food additives for improving the health of humans and animals, or as active ingredients in cosmetic products, protecting the skin against oxidation and pre-mature aging.

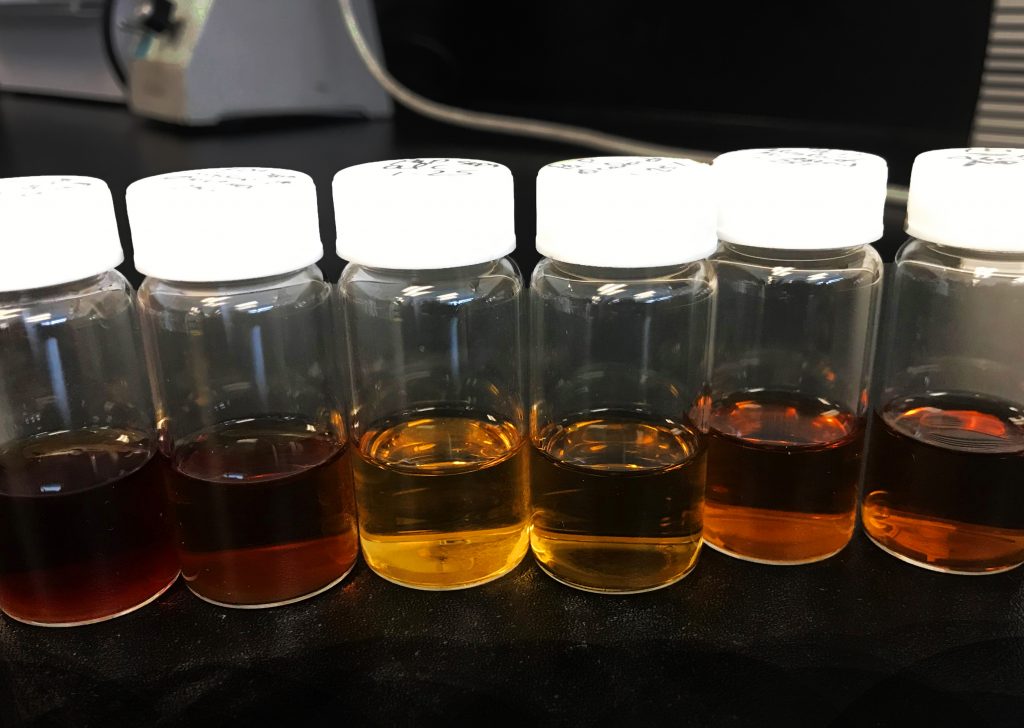

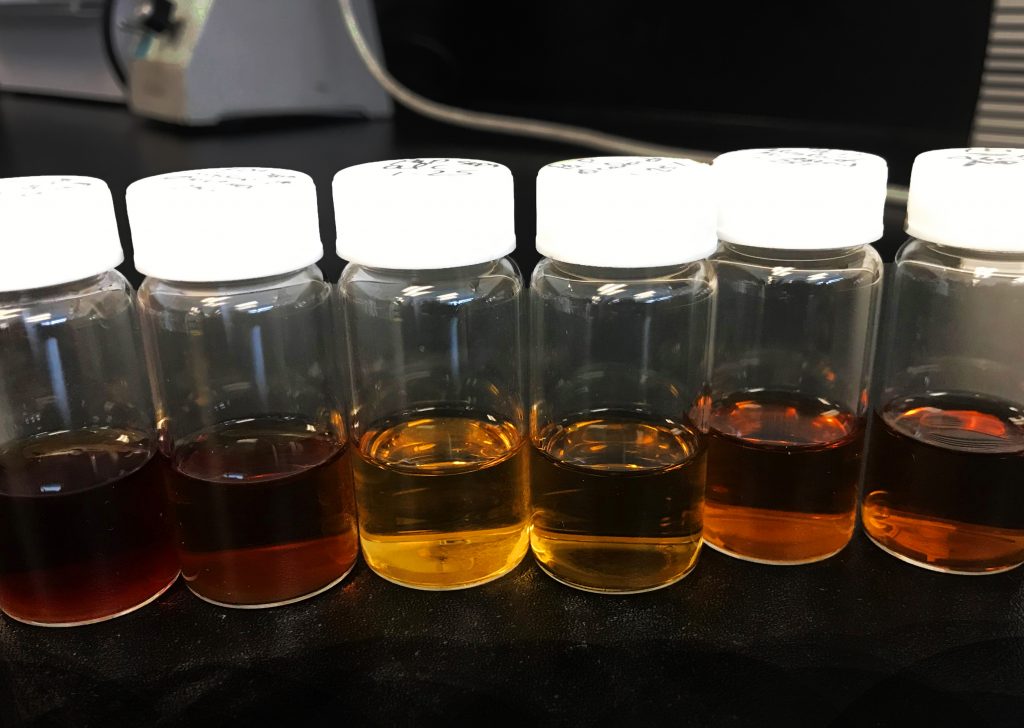

To isolate the active molecules from the bark residues, Innofibre has developed several extraction methods that have allowed to develop different mixtures of specialized compounds that vary according to the tree species being used, such as black spruce, trembling aspen, white birch, etc. Research on the antimicrobial activities of these various extracts produced in the laboratory has led to the interesting discovery that some contain molecules that limit the proliferation of certain pathogenic microorganisms, such as the bacteria E. coli and S. aureus, the mold, A. niger, and even against certain phytopathogenic fungus, such as Fusarium spp. Also, research conducted on the antioxidant activity, showed that some molecules within the extracts were able to interact and neutralize free radicals. According to the chemical characterization results, these antimicrobial and antioxidant properties seem to be correlated with the abundance of phenolic compounds, and more specifically, flavonoids and proanthocyanidins.

Recent research carried out by Innofibre has led to the development of an extraction method that concentrates proanthocyanidins using the bark from black spruce. This extract is so efficient that it meets Health Canada’s Safety and Efficacy Requirements for surface disinfectants! The chemical characterization work was carried out in collaboration with research centers specialized in this field and made it possible to identify which compounds are most likely responsible for the biological activity recorded. Tests performed on the isolated molecules showed that they all had antimicrobial potential, but that it wasn’t as efficient as when the molecules are all together as part of the extract. This clearly demonstrates that there is a synergistic action taking place between the compounds within the extract. Work is currently being done to further investigate and understand these positive interactions happening between the molecules of this complex mixture.

When Equipment and Expertise meet

Owing to Innofibre’s continuing expertise in the valorization of biomass, and more specifically that in the field of lignocellulosic fibres, the centre has acquired various types of specialized equipment over the years which have allowed the development of pilot-scale conditioning and extraction methods of different barks. These installations have also allowed to elaborate sieving and grinding methods which ensure the quality of the raw material used for extractions. A paper digester, which is a special piece of machinery used in the process of papermaking and that was already being used by Innofibre to carry out research for the paper industry, has allowed to develop an efficient subcritical extraction method, where increased temperatures and pressures significantly improved extraction yields. In addition, our research center has a new explosion-proof room with reactors having capacities of 200L and more which allow to realize pilot scale extractions with different solvents.

The exciting results of our numerous research projects have shown that there exist multiple opportunities for the valorization of bark biomass obtained from various tree species growing in Canada’s forests. This leads to our growing interest in bark exploitation as a value-added product, as we continue to invest in meeting the needs of companies, following current market trends, and remaining engaged in the development of new and emerging natural products.

Figure 1: Black Spruce bark Extract

Figure 2. 100L High Pressure Solinox Reactor

Figure 3: Aspen, White Birch and Black Spruce Extracts.