Author: Annabelle St-Pierre, Researcher at Innofibre

For over a decade, Innofibre has been exploring the phosphorylation process of cellulose to impart various desirable properties such as flame resistance, super absorbency, and strong cation exchange capacity. When applied to wood, this chemical modification can enhance materials resistance to environmental conditions including microorganisms and fire. This article aims to showcase Innofibre research on phosphorylating wood panels and the benefits of this application, addressing sustainability challenges in the construction industry.

Concerns about Durability and Health

While wood materials offer economic and ecological advantages over concrete or steel structures, lignocellulosic substrates are susceptible to fungal growth in humid environments. Locations like bathrooms, spas, boats and areas prone to water infiltration can experience fungal contamination, leading to economic and health issues. Wood degradation by fungi reduce mechanical properties and may require premature material replacement. Additionally, mold contamination causes aesthetic issues and compromises indoor air quality, potentially resulting in respiratory problems, allergies or fever.

Currently, several solutions exist to mitigate fungal proliferation and ensure optimal wood longevity including fungicidal additives, thermomechanical treatments, and chemical wood functionalization. Each treatment method presents its own advantages and disadvantages. An ideal solution that eliminates health and environmental risks while remaining economically viable remains elusive.

Metal Ions Combatting Fungal Growth

Recognizing these challenges, Innofibre has developed an innovative antifungal treatment as an alternative to existing market products. This involves cellulose phosphorylation followed by grafting of metal counter-ions. Phosphate groups addition increase cellulose electronegativity, facilitating the adsorption of metal cations such as Cu2+, Ni2+ or Zn2+, all known for their antimicrobial properties. This treatment approach aims to limit fungal proliferation on wood panels.

Figure 1. Phosphorylation Treatment of an OSB Panel

Less Rot in Our Walls

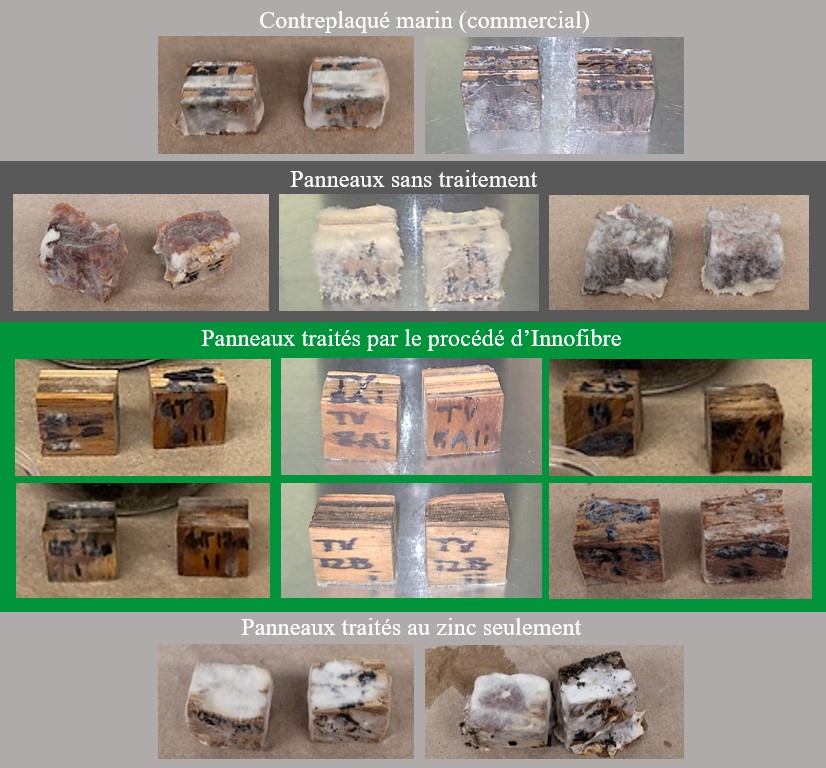

This project, funded by Quebec’s Ministry of Higher Education under the Research and Transfer Assistance Program (PART), was conducted from 2022 to 2023 and leading to promising results. The project explored various phosphorylation and counter-ion grafting conditions such as reaction time, reagent concentration, metal nature and treatment application methods. Plywood and oriented strand board (OSB) samples underwent standardized mold and rot tests, demonstrating significantly improved resistance compared to untreated samples.

In mold proliferation tests, treated panels showed significantly reduced mold growth, although none inhibited mold as effectively as commercially available marine plywood designed to resist fungi. Notably, in rot resistance tests measuring lignocellulosic mass loss due to rot organisms, phosphorylated and zinc-treated panels outperformed commercial marine plywood. This difference, visible to the naked eye, is illustrated in Figure 2.

Figure 2. Appearance of Panel Samples after Incubation with Decay Organisms

While achieving commercial product efficiency in mold inhibition requires further refinement, the treatment success in rot inhibition suggests substantial potential for the construction materials sector. By mitigating rots, these innovative materials could offer extended lifespan in extreme moisture conditions.

What about Other Properties?

The primary goal of structural panels, as their name suggests, is to uphold building structures. Hence, it was crucial to evaluate the treatment effect on wood mechanical properties in this project. Fortunately, results from tests conducted by SEREX (a college technology transfer center located in Amqui) demonstrated that this treatment had no significant impact on mechanical properties such as modulus of rupture, elastic modulus, or swelling percentage.

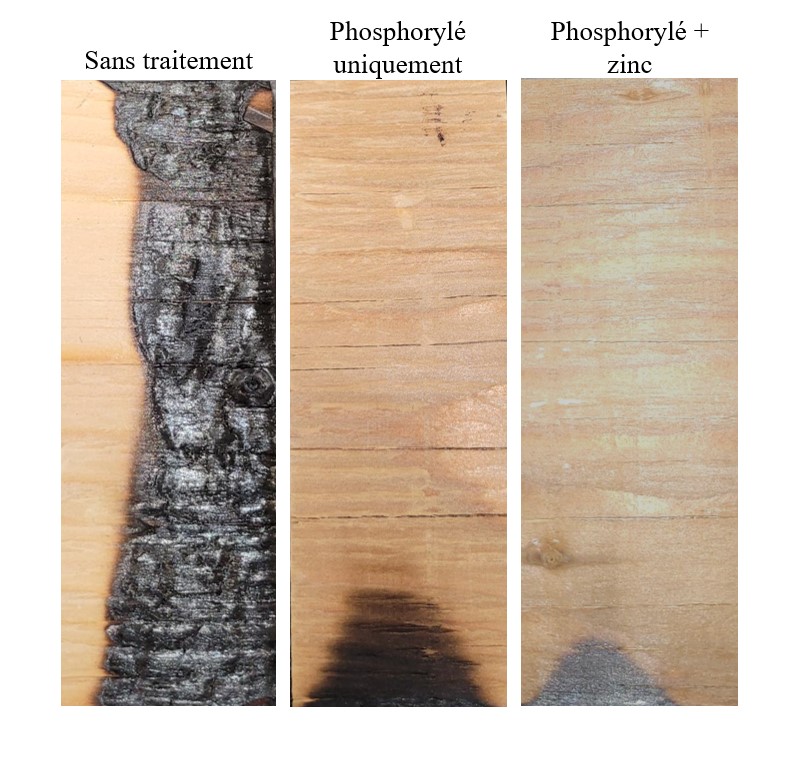

Moreover, what about the zinc treatment effect on the fire resistance properties of phosphorylated wood? Here too, Innofibre’s team ensured to measure the treatment impact on fire resistance capacity. Flame propagation tests were conducted on treated samples, revealing that the wood panels exhibited excellent fire resistance compared to untreated panels. This is another pertinent property for ensuring the durability of wood materials. Notably, both antifungal and fire resistance properties are achieved through a single treatment process.

Figure 3. Appearance of Plywood Samples after Flame Propagation Test