What the heck about hydrocyclones?

26 July 2024

Author: Gaston Michaud, Research Engineer, Innofibre

They are there, but we ignore them. We walk past them without a care in the world. Yet hydrocyclones are an integral part of most papermaking processes. They can be found, for example, in paper machine approach systems, in recycling and deinking plants, in kraft pulp plants and in thermomechanical pulp plants, to name a few.

Figure 1 : Picture of a heavy contaminant hydrocyclone bank

Figure 2 : Picture of a light contaminant hydrocyclone bank

The purpose of hydrocyclones is to remove contaminants and unwanted fibers from a fibrous suspension. The aim is to achieve acceptable pulp quality with minimal loss of good fibers and the lowest possible energy consumption.

They are identified in different ways. Some call them cleaners, cones or even bottles. Hydrocyclone systems have several stages. This means that there can be tens, even hundreds of hydrocyclones in a system. The stages following the first are used to recover the good fibrous material that has passed into the rejects and to concentrate contaminants. Systems are generally organized in cascades, with the rejects being reprocessed in the subsequent stages and the accepted material being directed to the preceding stages. In this way, an acceptable compromise is sought between dirt removal efficiency (or poorly developed fibers) and fiber loss.

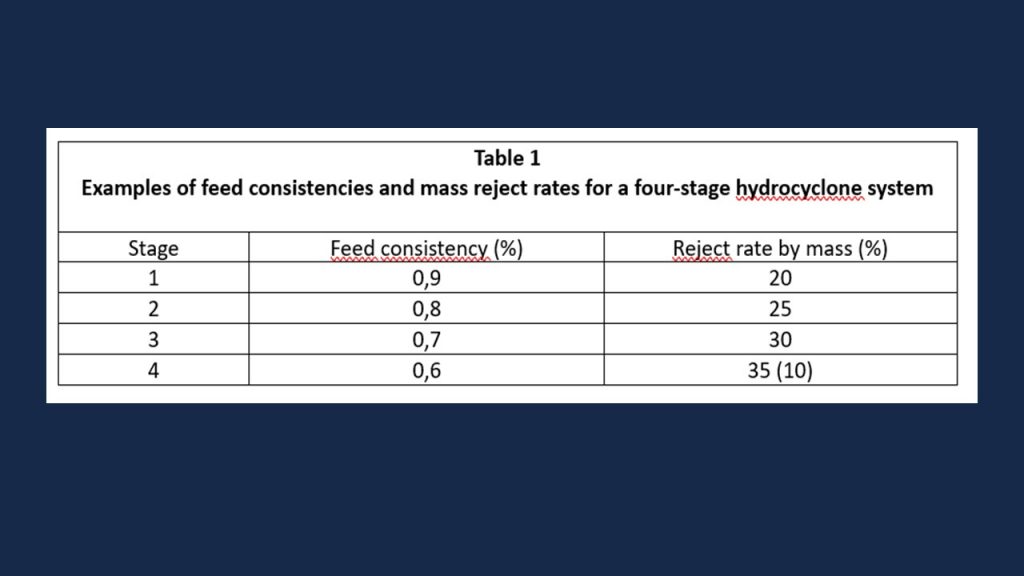

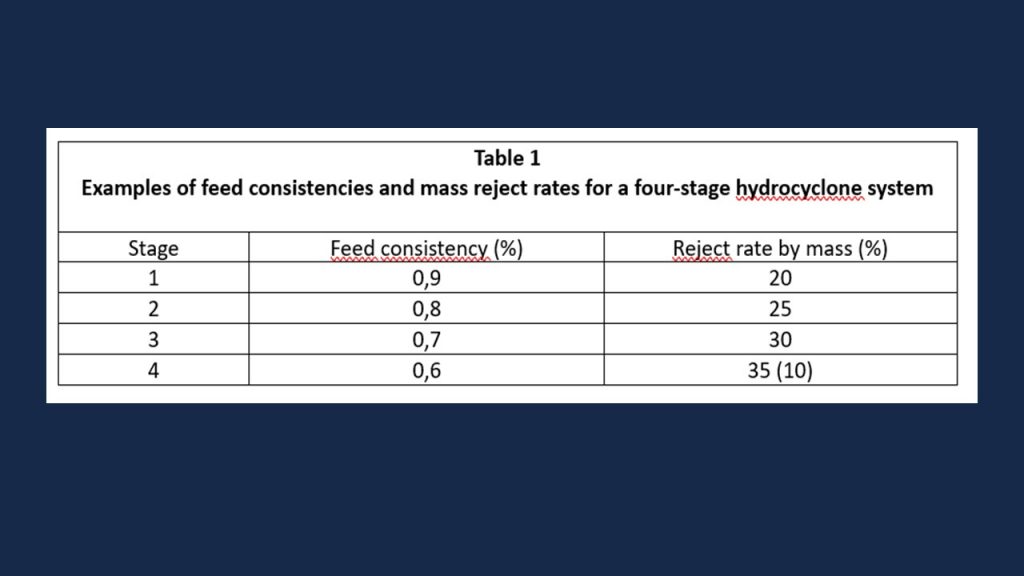

Hydrocyclones have a higher separation efficiency, the lower the feed consistency. Most hydrocyclones generally operate at a feed consistency of less than 1%. In multi-stage systems, feed consistency will be reduced from one stage to the next to promote separation efficiency, as contaminant concentration increases. For example, a four-stage system might have a consistency of 0.9% in the first stage, 0.8% in the second, 0.7% in the third and 0.6% in the fourth (Table 1). The high-density hydrocyclones found in recycling and deinking plants operate at a much higher feed consistency (4 – 5%), as they are designed to remove dense contaminants (stones, glass, paper clips, staples, bolts, nails, screws…). These are relatively easy to remove at a higher consistency.

The reject rate by mass also has a significant effect on separation efficiency. The higher the mass reject rate, the higher the separation efficiency of the hydrocyclones. In multi-stage systems, the mass reject rate will increase from stage to stage to promote separation efficiency since, as previously mentioned, the concentration of contaminants increases. For example, for a four-stage system, this rate could be 20% in the first stage, 25% in the second, 30% in the third and 35% in the fourth (Table 1). Typically, the effective reject rate for the fourth stage will be much lower (around 10%), as this stage is equipped with a fiber recovery system to limit losses. The reject rate can be modified by changing the reject opening, the accept pressure or the reject pressure.

When starting up a new installation, a lot of attention is paid to hydrocyclone systems. Care is taken to balance the system so that it meets the performance criteria for which it was designed. In terms of mechanical construction, hydrocyclones are simple devices. They have no moving parts. Over time, we forget about them. They are even neglected until quality problems are reported. Dirt finds its way into the sheet of paper, the sheet of paperboard or the pulp. Then it’s time to look for the source of these problems. Investigation reveals that the hydrocyclones are in poor condition: leaks, perforations, plugging, wear and tear…. It often turns out that the system is no longer working as it should. Operating pressures and consistencies are no longer respected. Pressure transmitters are inaccurate or simply don’t work. Reject rates no longer correspond to optimum values. Somehow, we have lost control of the system’s operation. We’re just pumping pulp through them as if they were mere pieces of pipe. Not only does this result in a loss of performance, this is also a waste of energy.

To avoid losing control, it’s important to monitor hydrocyclones regularly, as you would with any other piece of equipment. Minimal maintenance is required. Worn parts must be replaced. Pressure transmitters should be checked for calibration. It is essential to correctly measure feed consistencies and determine reject rates for each stage of the system.

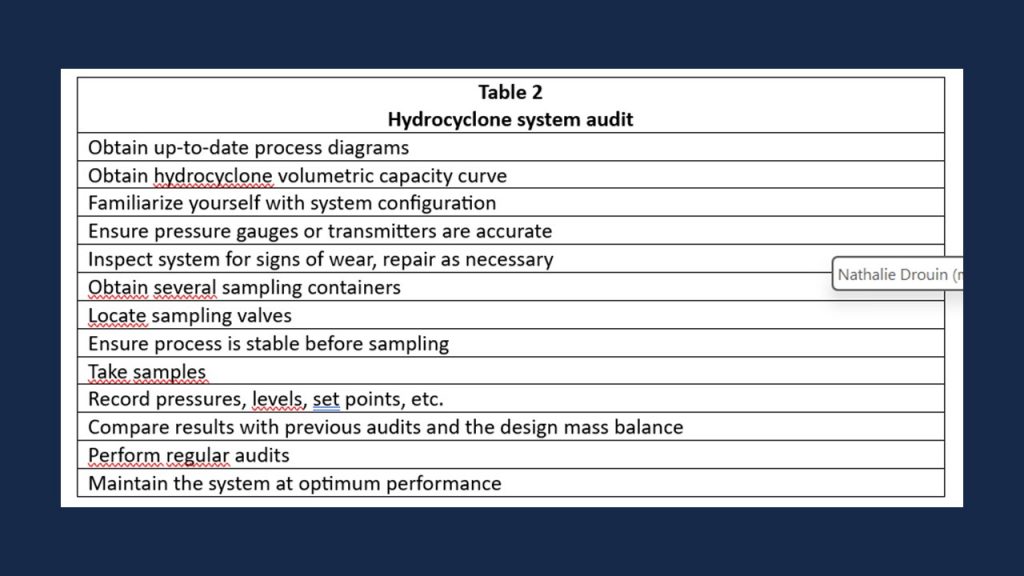

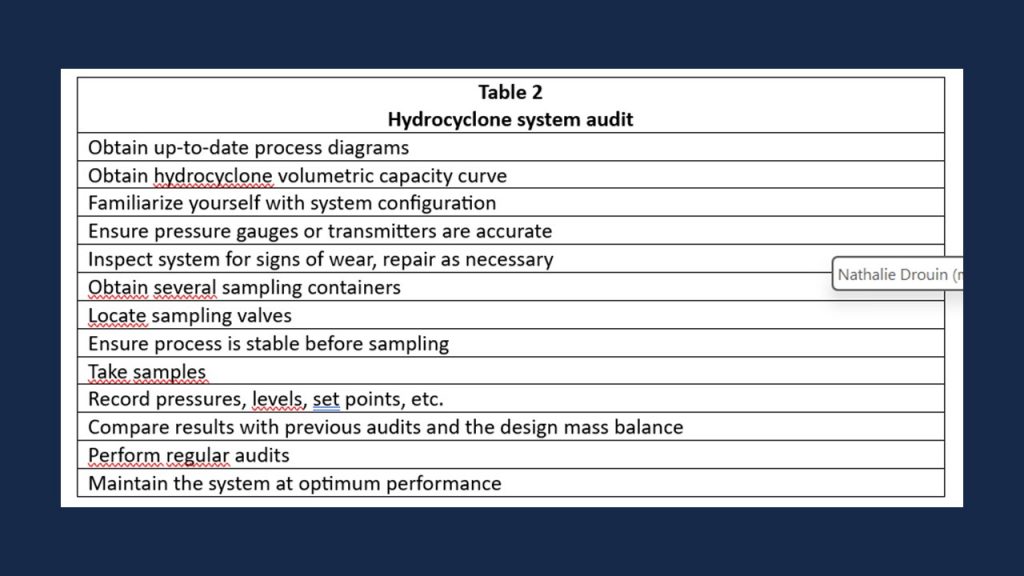

For this type of system, volumetric and mass balances are essential to get a clear picture of the operation. It is suggested that regular balances be carried out to ensure proper follow-up. At the very least, one should be done per year, and even two if possible. This will enable to compare the balances with each other and identify any deviations. If these are significant, the necessary adjustments will be made to return to optimal operation. If new operating conditions are required to respond to upstream or downstream changes, these will be noted and communicated. Before undertaking such an audit (Table 2), make sure that pressures are measured accurately. Pressure transmitters must be calibrated and properly positioned. Control valves must be in good working order. Hydrocyclones must be in good condition. When carrying out the balance, it must be possible to take representative samples of each stream (feed, accept, reject) at each stage. Operating conditions must be noted (setpoints, pressures, valve openings, number of hydrocyclones per stage, flow rates).

What the heck about hydrocyclones? They clean the pulp and maintain its quality, provided they are properly monitored.

To refurbish hydrocyclone systems, contact your hydrocyclone supplier for assistance. Innofibre’s specialists can also give you a hand. If you feel that training is necessary to give your operators a better understanding of how a hydrocyclone system works, don’t hesitate to contact Innofibre.